Jump to

Semiconductor Overview

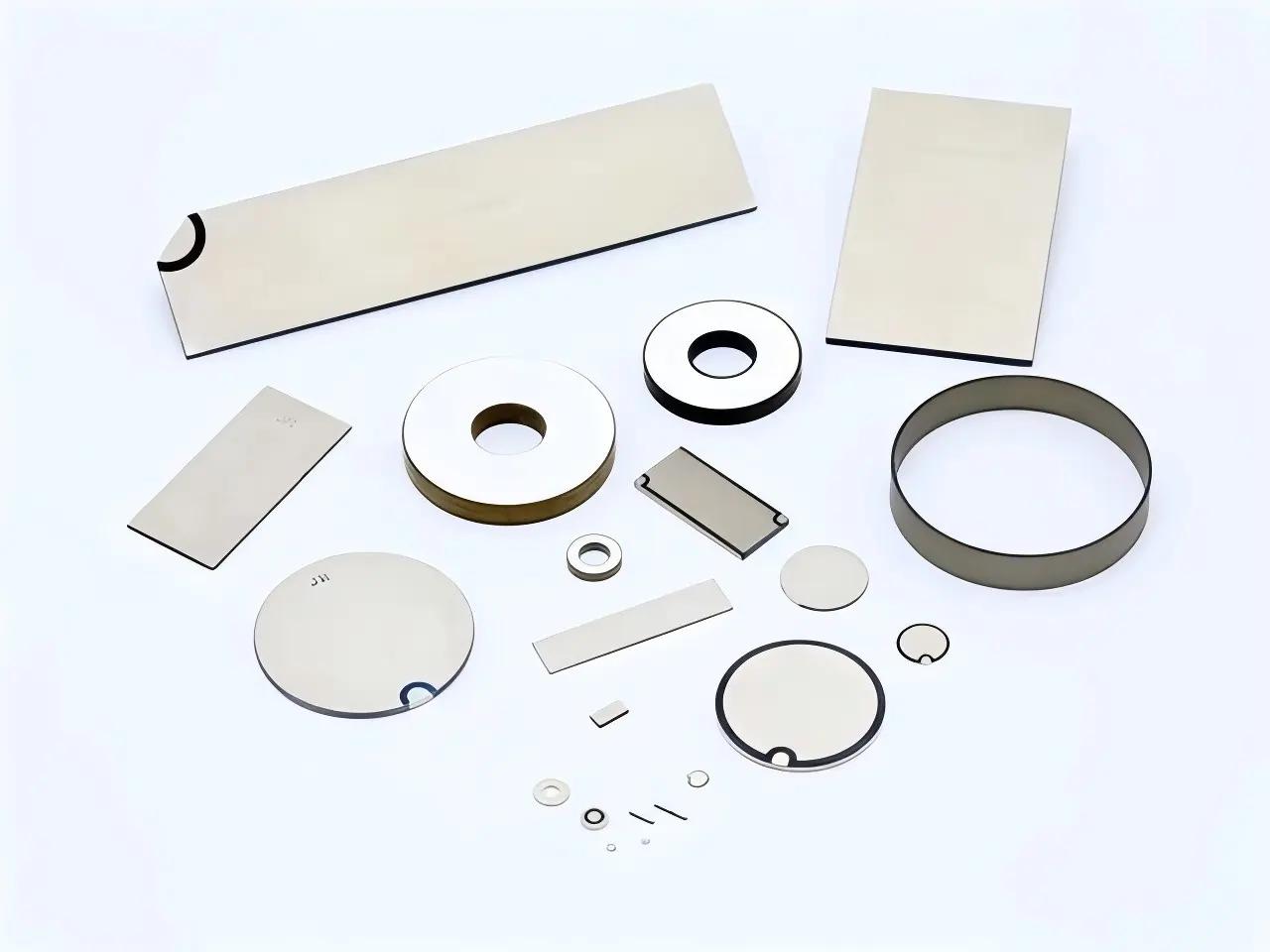

Loongceram is your partner in driving semiconductor process innovation. We have the semiconductor and materials portfolio, component manufacturing capabilities and application engineering services to help you meet your big challenges. Engineered technical ceramics are widely used in the semiconductor industry due to their excellent material properties. Our ultrapure ceramics are typically used throughout the entire cycle of semiconductor manufacturing and semiconductor processing.

Loongceram is your partner in driving semiconductor process innovation. We have the semiconductor and materials portfolio, component manufacturing capabilities and application engineering services to help you meet your big challenges. Engineered technical ceramics are widely used in the semiconductor industry due to their excellent material properties. Our ultrapure ceramics are typically used throughout the entire cycle of semiconductor manufacturing and semiconductor processing.

<strong>Material Characterization for Semiconductor Manufacturing</strong><br>Whether in wafer processing, semiconductor fabrication or handling, <br>our components made of high-performance ceramics deliver long-lasting <br>performance and reliability.

- Alumina (Aluminum Oxide): Alumina is widely used for its high electrical insulation, thermal conductivity, and mechanical strength.

- Aluminum Nitride (AlN): Aluminum Nitride exhibits high thermal conductivity, making it suitable for semiconductor packages and substrates. It is often used in applications requiring efficient heat dissipation.

- Silicon Nitride (Si3N4): Silicon Nitride offers excellent mechanical strength, thermal shock resistance, and resistance to wear. It is utilized in semiconductor processing equipment, as well as components like bearings and wafer chucks.

- Zirconia (Zirconium Oxide): Zirconia is known for its high strength, toughness, and resistance to wear. It is employed in various semiconductor components, including precision bearings and insulators.

- Silicon Carbide (SiC): Silicon Carbide is valued for its high thermal conductivity, chemical resistance, and hardness. It is used in semiconductor applications such as power electronics, where high-temperature stability is crucial.

- Boron Nitride (BN): Boron Nitride is known for its thermal stability, electrical insulation properties, and lubricity.

- Ceramic Matrix Composites (CMCs): CMCs, combining ceramic fibers with a ceramic matrix, offer enhanced mechanical properties and find applications in semiconductor manufacturing equipment.

<strong>Semiconductor Product Capabilities</strong>

Sedimentation process

Etching process components

Lithography and wafer inspection

Ion implantation

Diffusion and LPCVD processing Treatment

Rapid Heat Treatment

Semiconductor package

Allgemeine Anwendungen und Wafer-Handling

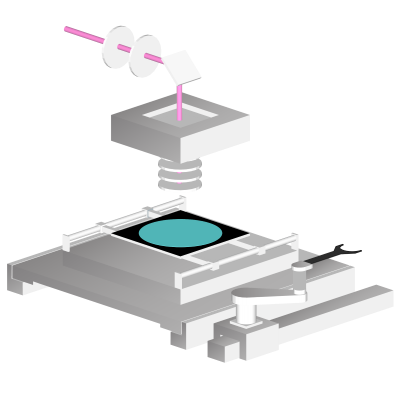

Sedimentation process

Semiconductor deposition processes use a combination of

volatile precursor gases, plasma and high temperatures to

deposit high quality thin films on wafers. Deposition chambers

and wafer handling tools require durable ceramic components

to withstand these harsh environments.

Deposition chamber assembly

The inert and durable properties of engineered ceramics are required

wherever process equipment is exposed to harsh deposition conditions

or in contact with wafers.

Etching process components

loongceram’s high-purity ceramic components are designed to withstand the

extreme environments found in plasma etch (or “dry” etch) chambers –

including gas-phase chemical etchants, high-pressure RF and microwave

plasma, volatile by-products, and aggressive cleaning cycles.

Ceramic parts for plasma etching equipment

Minimize contamination and unplanned maintenance with high-purity

components designed for harsh plasma etch processing, including:

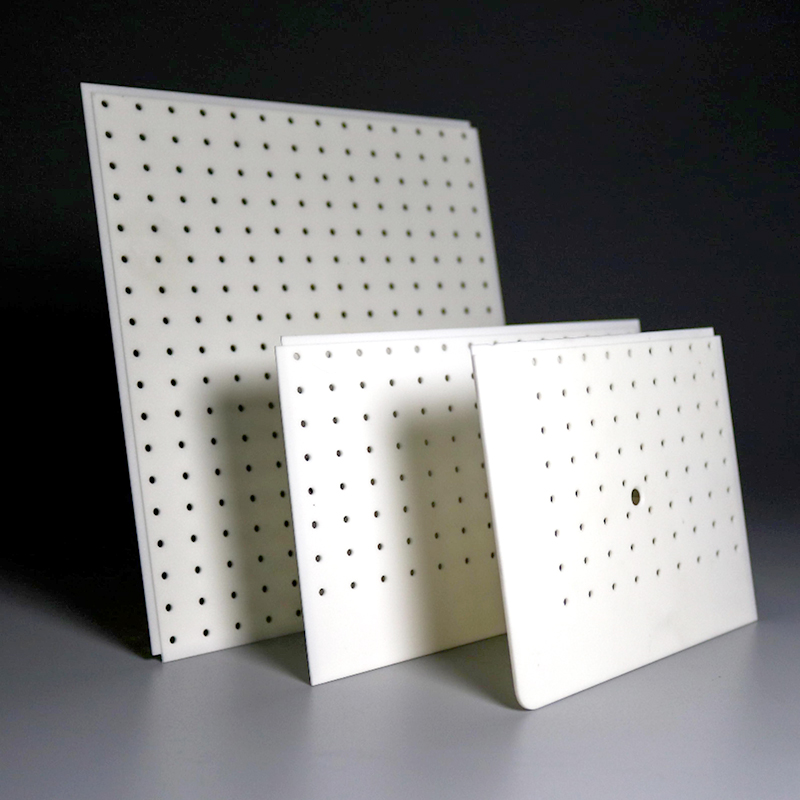

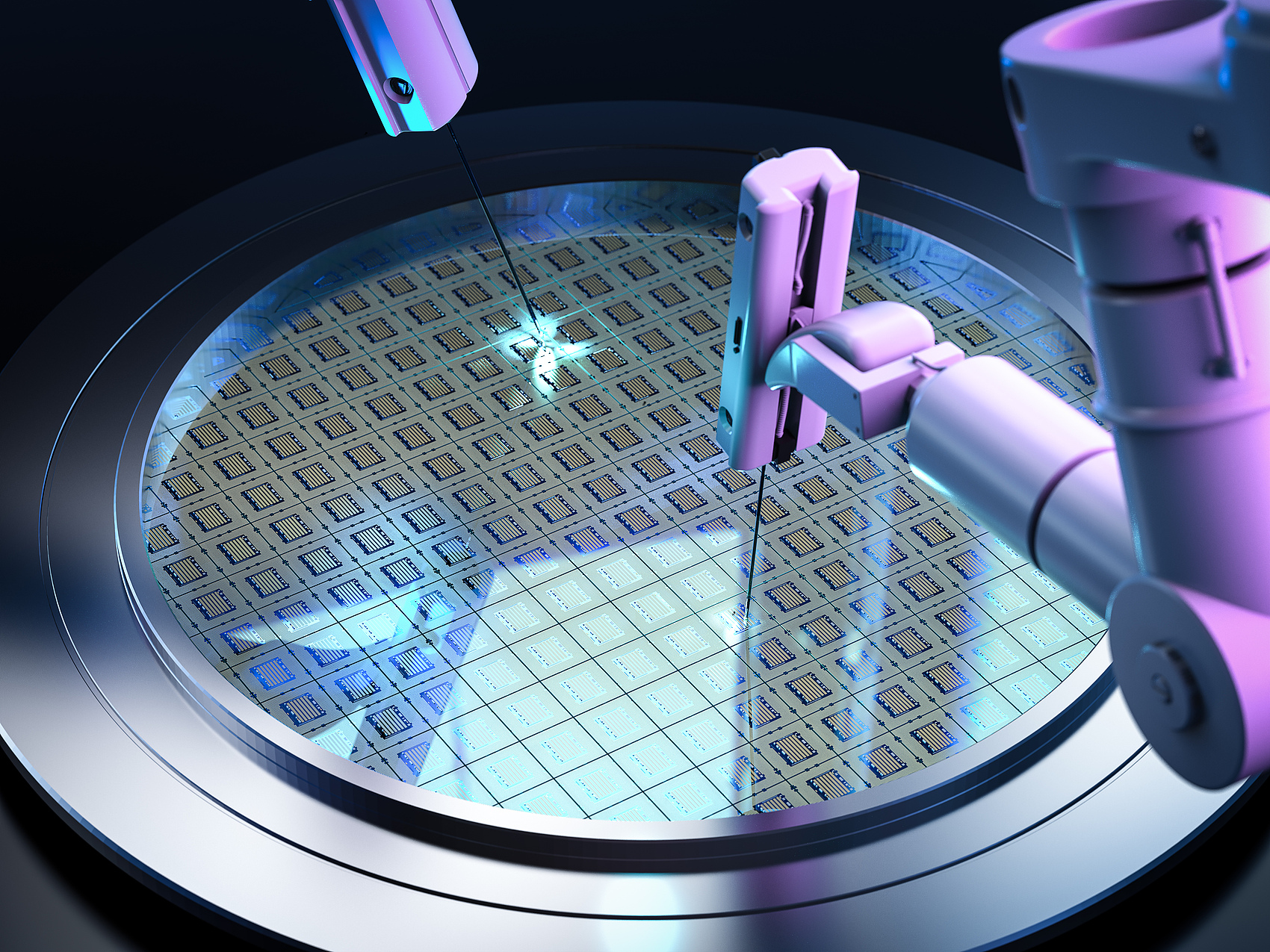

Lithography and wafer inspection

loongceram ultrapure ceramic components are ideally suited for next-

generation lithography and wafer handling applications, ensuring minimal

contamination and providing extremely long service life.

Lithography and wafer inspection components

Chemically resistant and thermally stable, loongcrea’s high-purity ceramic

components are ideal for lithography, wafer handling (low contamination),

and wafer inspection (very high durability and hardness, dimensional stability).

Applications include:

Ion Implantation

From precision air bearing assemblies and beams, to ultra-flat vacuum suction cups and thermally stabilized pins, screws, and frames, advanced ceramic components are designed to meet the demanding requirements and precision characteristics of the ion implantation process.

From precision air bearing assemblies and beams, to ultra-flat vacuum suction cups and thermally stabilized pins, screws, and frames, advanced ceramic components are designed to meet the demanding requirements and precision characteristics of the ion implantation process.

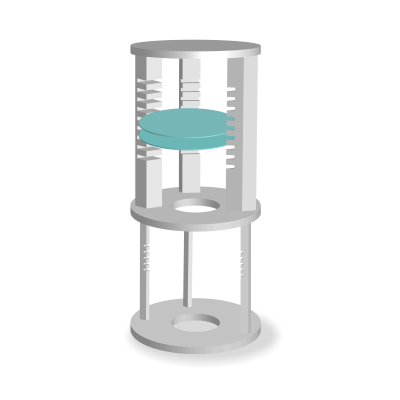

Diffusion and LPCVD processing

Traditional diffusion, low pressure chemical vapor deposition (LPCVD), and

other bulk semiconductor applications require the heat resistance and purity

characteristics of advanced ceramics. loongceram offers engineered ceramic

components specifically designed to meet the requirements of bulk diffusion

and LPCVD.

Engineering Ceramic Components

Loongceram bietet keramische Komponenten an, die für Bulk-Diffusion und

LPCVD-Anforderungen entwickelt wurden, einschließlich:

Rapid Thermal Processing

Technical Ceramics ist die natürliche Wahl für thermische Verarbeitungsanwendungen

in der Halbleiterindustrie, einschließlich Rapid Thermal Processing (RTP), Epitaxie,

Diffusion, Oxidation und Glühen.

Komponenten für schnelle Wärmebehandlung und Epitaxieverfahren

Loongceram bietet fortschrittliche Materialkomponenten an, die so konzipiert sind,

dass sie Wärmeschocks mit hoher Reinheit und robuster, wiederholbarer Leistung für Hochtemperaturprozesse standhalten:

Technical Ceramics ist die natürliche Wahl für thermische Verarbeitungsanwendungen

in der Halbleiterindustrie, einschließlich Rapid Thermal Processing (RTP), Epitaxie,

Diffusion, Oxidation und Glühen.

Komponenten für schnelle Wärmebehandlung und Epitaxieverfahren

Loongceram bietet fortschrittliche Materialkomponenten an, die so konzipiert sind,

dass sie Wärmeschocks mit hoher Reinheit und robuster, wiederholbarer Leistung für Hochtemperaturprozesse standhalten:

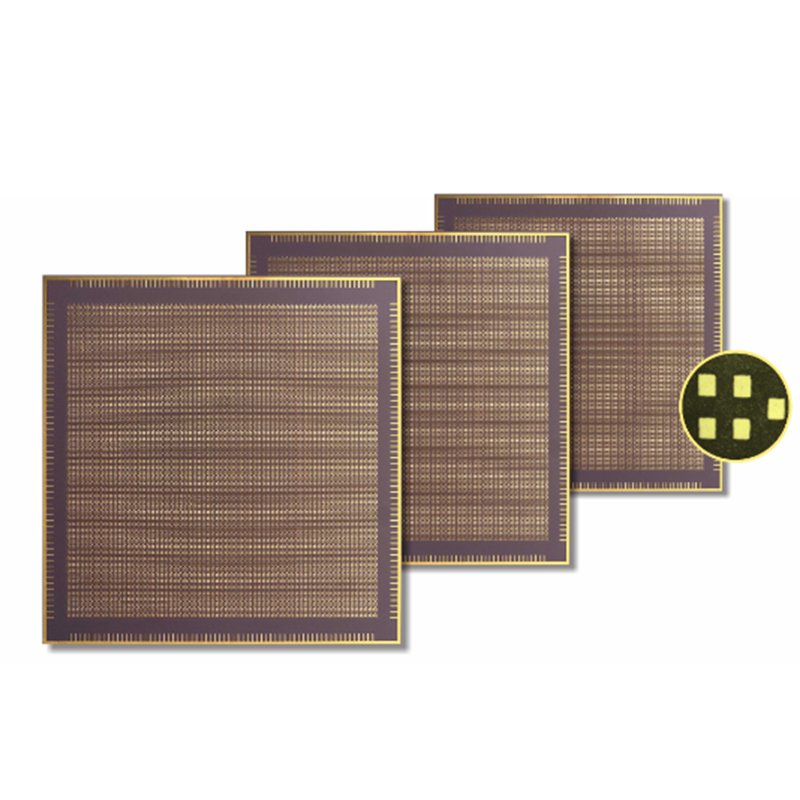

Semiconductor package

Advanced ceramics have become an irreplaceable material in semiconductor packaging through excellent thermal conductivity, insulation, mechanical and chemical stability, especially in the high-end field (high-frequency, high-power, high-reliability) to occupy a dominant position. In the future, with the development of semiconductor technology to smaller size and higher integration, the innovation of ceramic materials will further enhance the performance of packaging, our products in semiconductor packaging include:

General Purpose Applications and Wafer Handling

We are your partner in customizing advanced ceramic components and

assemblies to help your semiconductor processing equipment achieve highe

r yields and productivity. Our materials experts are ready to work with you

to develop the best solutions for your wafer handling, heating and processing

needs.

Semiconductor Processing Ceramics Questions+

How is ceramic used in semiconductor processing equipment?+

Ceramic components provide a clean surface, dimensional stability and resistance to degradation in semiconductor

processing equipment such as chamber linings and rings.

processing equipment such as chamber linings and rings.

Why are ceramics used in semiconductor processing equipment?+

Loongeram CVD SiC ceramic material has a unique combination of excellent thermal, electrical and chemical properties that makes it well-suited to applications across

semiconductor industries where a high-performance material is required.

semiconductor industries where a high-performance material is required.

What are the advantages of Loongeram semiconductor products?+

1.Ultra-pure 99.999%

2.Outstanding corrosion resistance in plasma applications

3.Proven durability in high temperature ammonia environments

4.Excellent thermal shock resistant

5.High thermal conductivity

6.Excellent stiffness to weight ratio

7.Fine grained microstructure

8.Non-porous

9.Two resistivity grades

2.Outstanding corrosion resistance in plasma applications

3.Proven durability in high temperature ammonia environments

4.Excellent thermal shock resistant

5.High thermal conductivity

6.Excellent stiffness to weight ratio

7.Fine grained microstructure

8.Non-porous

9.Two resistivity grades

<strong>Recommendations for medical and pharmaceutical products</strong>