Equipment And Preparation

Powder to Green Body Preparation

Powder to Green Body Preparation

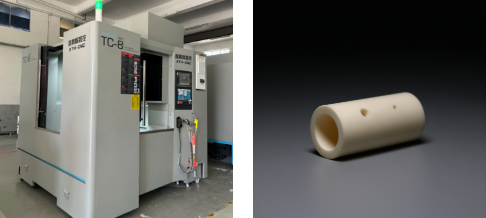

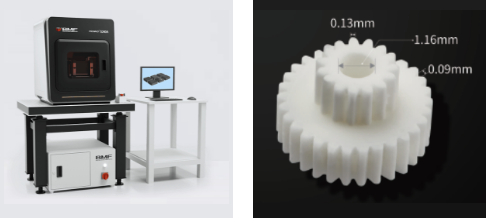

Loongceram breaks through the traditional model and integrates technologies such as granulation, ceramic forming, green body processing, sintering, and machining into a single entity through an innovative approach. Coupled with a systematic detection and control process, it has created an integrated production and manufacturing platform.

Loongceram has established a large modern manufacturing plant in Shenzhen with complete supporting facilities and in line with international standards. It comprehensively applies advanced software such as ProE, Lotus, PDM, and ERP, and introduces high-end and advanced production and testing equipment to ensure that Shangde’s advanced ceramic products can meet the highest international quality standards.

Loongceram has established a large modern manufacturing plant in Shenzhen with complete supporting facilities and in line with international standards. It comprehensively applies advanced software such as ProE, Lotus, PDM, and ERP, and introduces high-end and advanced production and testing equipment to ensure that Shangde’s advanced ceramic products can meet the highest international quality standards.

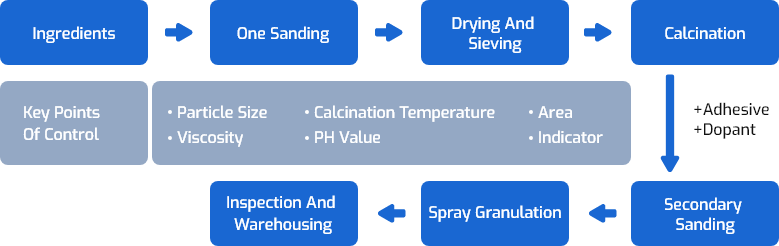

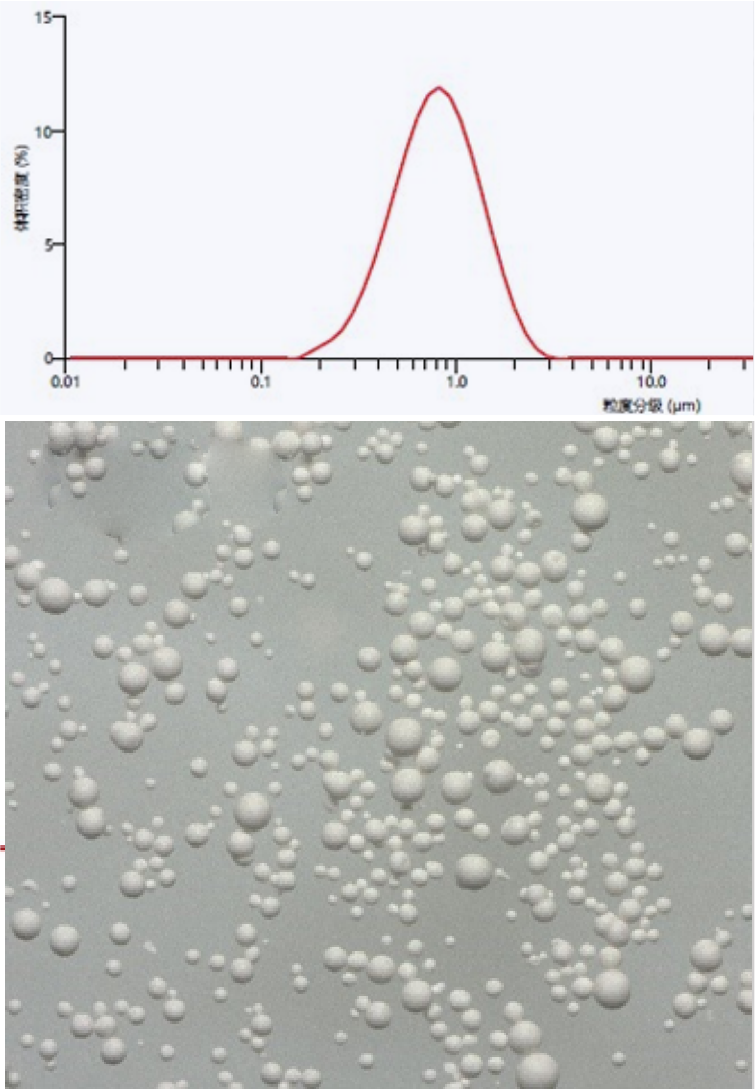

Powder preparation process

Preparation of dielectric ceramics by solid-phase method

According to the special performance requirements of customers, customized designs such as performance modification or color customization can be carried out from the perspective of formula

Powder preparation equipment

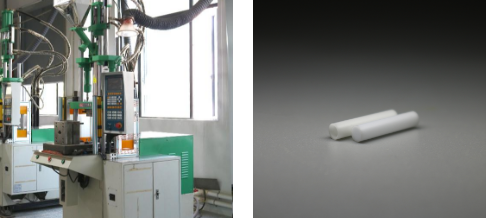

Forming Process Diversity

Loongceram has 5 Forming techniques: dry pressing, high pressure injection olding, low pressure injection molding, Isostatic pressing molding, gel casting molding.

In accord with customers specific structure, size, accuracy and quantity requirements, we choose suitable molding technique.

In accord with customers specific structure, size, accuracy and quantity requirements, we choose suitable molding technique.

- Dry pressing forming+

Forming Advantages:

Forming Advantages:

It features high production efficiency, high repeatability, short production cycle, simple and convenient operation. The products produced have high density and strength, making it suitable for large-scale industrial production.

Forming Disadvantages:

There are significant restrictions on the shape of the formed products, the mold cost is high, the strength of the formed green body is low, the internal density of the complex green body is inconsistent, and the uniformity of the microstructure is relatively poor - Isostatic pressing forming+

Forming Advantages:

Forming Advantages:

The product has a uniform microstructure, high density, low sintering shrinkage rate, and low mold cost. It can be formed into complex-shaped, slender, large-sized and precision-sized products

Forming Disadvantages:

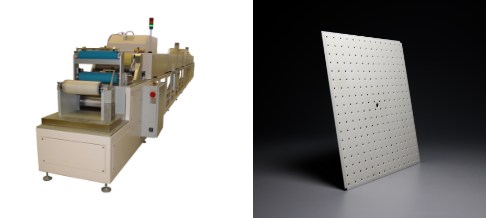

The process is rather complex, the precision of the produced blanks is low, the surface is relatively rough, and further processing and grinding are required, resulting in low production efficiency. - Casting molding+

Forming Advantages:

Forming Advantages:

Thin and uniform ceramic films can be prepared, and functional ceramics such as monolithic capacitor ceramic sheets, multi-layer wiring ceramic sheets, and thick and thin film circuit substrates can be produced. The process is stable, and the repeatability of the formed green body performance and the consistency of the size are relatively high.

Forming Disadvantages:

A large amount of organic solvents are needed in the production process, which poses certain environmental and safety issues. Moreover, the equipment cost is relatively high and the production efficiency is relatively low. - Injection molding+

Forming Advantages:

Forming Advantages:

It is capable of manufacturing ceramic parts with complex shapes and high dimensional accuracy, featuring high production efficiency and the ability to achieve large-scale production.

Forming Disadvantages:

The cost of equipment and molds is high, the requirements for ceramic powder and binders are high, the preparation process of injection materials is complex, and the degreasing process is rather crucial. Improper handling is prone to cause defects - Gel injection molding+

Forming Advantages:

Forming Advantages:

It features near-net-size molding, low organic matter content, high body strength and is suitable for mechanical processing, making it ideal for large-scale batch production.

Forming Disadvantages:

Strict requirements are imposed on raw materials and process control. The selection and dosage of additives such as monomers and initiators affect the quality of the green body, and shrinkage and deformation may occur during the curing process. - 3D printing forming+

Forming Advantages:

Forming Advantages:

It can achieve highly personalized customization, produce complex and uniquely shaped ceramic parts without molds, and is convenient for design modification, enabling rapid prototyping.

Forming Disadvantages:

The cost of equipment and materials is high, the printing speed is slow, the precision is limited, and the printing process for some high-performance ceramic materials is not yet mature.

Sintering process

Spray drying tower

It can be applied to various types of process and production control. It enables

Degreasing Calcining Furnace

It Can Be Applied To Various Types Of Process And Production Control. It Enables

Muffle Furnace

It Can Be Applied To Various Types Of Process And Production Control. It Enables

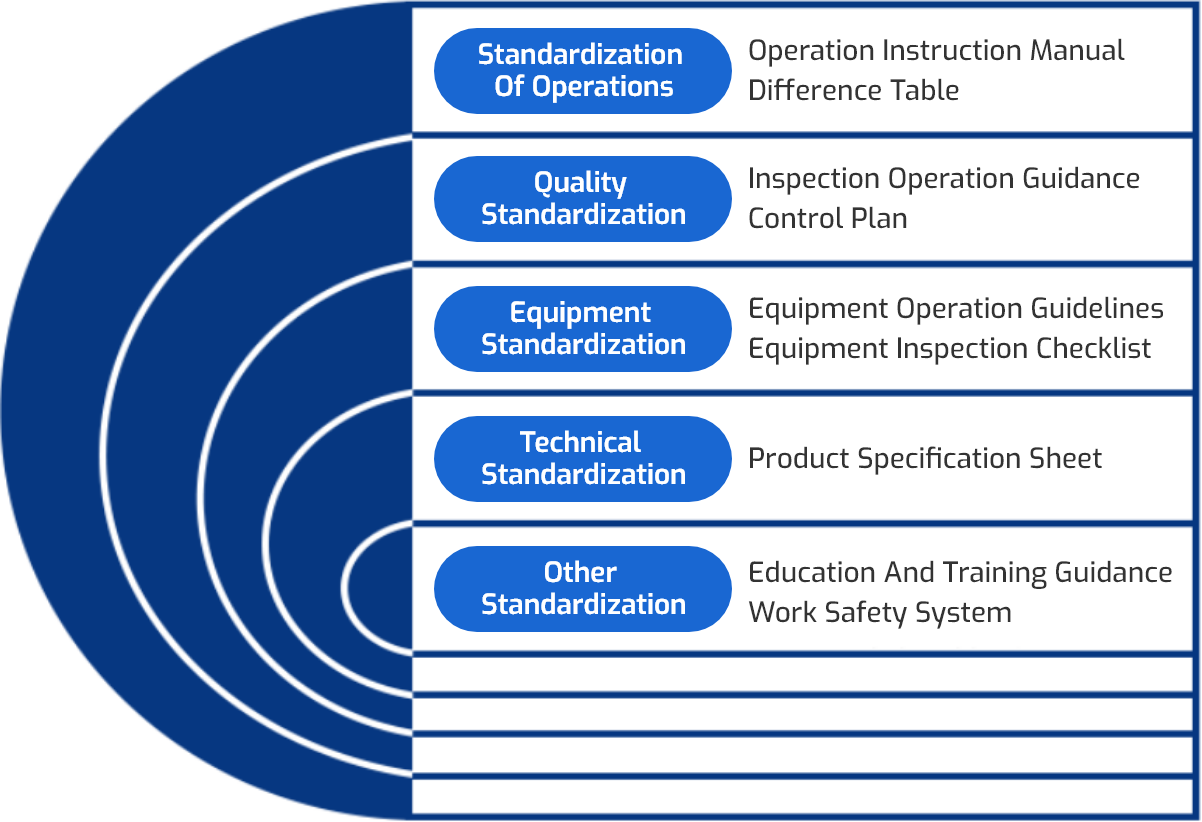

On-site management

- It is mainly supported by three pillars: standardization, visualization and kanban. Standardization is the foundation of benchmarking management, Kanban increases precision, and visualization reduces difficulty.

- Standardization: It is mainly reflected in the standardization of operations, quality, equipment, technology and other aspects.

- Visualization: Create a “clear at a glance” workplace. Through visual tools such as kanban boards, signs, physical objects, lights, and charts, define the direction, location, distance, trend, and differences of people, events, and objects, manage the site, and improve activities.

- Kanban management: Kanban management is an important component of first-class on-site management. Through various kanban boards, the management status is displayed to the public, enhancing transparency and creating an internal management atmosphere. Enhance customer satisfaction, reduce management costs and lower management risks.