Alumina Al₂O₃

Alumina

Alumina ceramics are renowned for their exceptional hardness and are a robust type of industrial oxide ceramic.

Favored by many manufacturers, alumina ceramics offer numerous advantages, including high thermal conductivity, excellent electrical insulation, corrosion resistance, a high melting point, and outstanding hardness. These properties make alumina ceramics a preferred material for a wide range of manufacturing processes.

Favored by many manufacturers, alumina ceramics offer numerous advantages, including high thermal conductivity, excellent electrical insulation, corrosion resistance, a high melting point, and outstanding hardness. These properties make alumina ceramics a preferred material for a wide range of manufacturing processes.

Advantages

- Excellent electrical insulation properties

- High hardness and mechanical strength

- Wear and abrasion resistant

- High thermal conductivity and thermal shock resistance

- Low density

- Resistant to strong acid and alkali attack at high temperatures

- Transparent to microwave radio frequencies

- High compressive and dielectric strength

- Very specific thermal conductive and thermal expansion rates

Material grade

CeramAlox 96

CeramAlox 99.7

CeramAlox 99.95 Ultra Pure

Overview

CeramAlox 96 is a regular purity grade Alumina (Aluminum Oxide) and its one of the workhorses of the technical ceramics industry. It features a 96% purity Alumina base material providing a balanced “cost to quality” ratio. It is a hard-wearing technical ceramic offering an excellent combination of both mechanical and electrical properties and is ideally suited to a wide range of industrial applications where cost is of the essence, but the material still needs to perform adequately from a mechanical and electrical standpoint.

CeramAlox 96 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

CeramAlox 96 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Applications

- Electronic components & substrates

- High temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

Overview

CeramAlox 99.7 it’s a high purity grade Alumina (Aluminum Oxide) and its one of the high performance grades in this range of materials. It features a 99.7% purity Alumina base material providing a superior set of mechanical and electrical properties while maintaining a reasonable cost. CeramAlox 99.7% is a very hard-wearing technical ceramic offering and is ideally suited to a wide range of industrial applications where mechanical and electrical performance is of the essence and the material needs to perform adequately in aggressive environments.

CeramAlox 99.7 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

CeramAlox 99.7 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

Applications

- Electronic components & substrates

- High temperature electrical insulators

- High voltage insulators

- Laser tubes

- Machined components

- Mechanical seals

- Precision shafts and axles in high wear environments

- Roller and ball bearings

- Seal rings

- Semiconductor parts

- Shot blast nozzles

- Thermocouple tubes

- Tap plates

- Valve seats

- Wear components

- Wire and thread guides

- Ballistic Armor

Overview

CeramaAlox Ultra Pure is a very high purity (99.95%) grade of Alumina (Aluminum Oxide) exhibiting an exceptional combination of mechanical and electrical properties. It features very high hardness, exceptional electrical resistivity, high temperature mechanical stability and strength in addition to corrosion resistance and bio/chemical inertness.

Its high temperature stability and electrical stability make it particularly suitable for high temperature applications such as high voltage/frequency insulators, heating elements supports, etc.

Its high temperature stability and electrical stability make it particularly suitable for high temperature applications such as high voltage/frequency insulators, heating elements supports, etc.

Applications

- High temperature electrical insulators

- Very high voltage/frequency insulators

- Machine components where high wear resistance

- is required in an oxidizing environment

- Precision shafts in high wear condition

- Unlubricated (vacuum) or gas/water lubricated

- high speed sliding bearings

- Shot blast nozzles

- Abrasive flow deflector plates/cones

- Valve seats

- Wire guides

Alumina Material Properties

Mechanical Properties

Thermal Properties

Electrical Properties

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Density | g/cm3 | 3.75 | 3.95 | 3.98 |

| Compressive Strength | MPa | 2000 | 2000 | 3500 |

| Tensile Strength | MPa | 140 | 150 | 200 |

| Flexural Strength @ 25°C | MPa | 200-300 | 250-350 | 500-600 |

| Fracture Toughness KIC | MPa m1/2 | 4.5 | 4 | 4.5 |

| Hardness | GPa | 12 | 14 | 18 |

| Young’s Modulus | GPa | 300 | 370 | 400 |

| Poisson’s Ratio | – | 0.23 | 0.23 | 0.23 |

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Thermal Conductivity @ 25°C | W/mK | 25 | 33 | 45 |

| Thermal Shock | – | Good | Good | Good |

| CTE1 25°C ➞ 300°C | 10-6/K | 6.3 | 6.5 | 7.5 |

| CTE1 25°C ➞ 700°C | 10-6/K | 7.0 | 7.5 | 8.0 |

| Maximum Temperature (Inert) 2 | °C | 1600 | 1700 | 1750 |

| Property | Unit | 96% | 99.7% | 99.95% |

|---|---|---|---|---|

| Dielectric Constant @ 1 MHz | – | 9.8 | 9.9 | 9.9 |

| Dielectric Constant @ 10MHz | – | 9.6 | 9.7 | 9.7 |

| Dielectric Strength DC @ 25°C | kV/mm | 9 | 11 | 16 |

| Dielectric Loss | 1 MHz | 0.0001 | 0.0001 | 0.0001 |

| Volume Resistivity @ 25°C | ohm-cm | >1014 | >1014 | >1016 |

Alumina Machining

Alumina can be produced in various purities by adding additives to enhance its performance. The common purity range is from 90% to 99.9%, but Longci Ceramics typically use materials with a purity of 99.7%.

It can be processed by injection molding, compression molding, isostatic pressing, grouting molding and extrusion molding, etc. After sintering, processing can only be carried out using the diamond grinding method. The advanced green body and blank processing technology developed by Precision Ceramics Company enables the manufacture of more complex components using traditional processing methods. In addition, alumina can be easily bonded to metals or other ceramics through metallization and brazing techniques.

Alumina can be processed in green billets, billets or in a completely dense state. In the green or billet state, alumina can be processed into complex geometric shapes relatively easily. However, in order to fully densify the material, the sintering process will cause the alumina green body to shrink by approximately 20%. This shrinkage means that when processing alumina before sintering, very strict tolerances cannot be maintained. To achieve very strict tolerances, diamond tools must be used to process/grind fully sintered materials. During this manufacturing process, very precise diamond-coated tools/grinding wheels are needed to grind the material until the desired shape is formed. Due to the inherent toughness and hardness of the material, this can be a time-consuming and costly process.

It can be processed by injection molding, compression molding, isostatic pressing, grouting molding and extrusion molding, etc. After sintering, processing can only be carried out using the diamond grinding method. The advanced green body and blank processing technology developed by Precision Ceramics Company enables the manufacture of more complex components using traditional processing methods. In addition, alumina can be easily bonded to metals or other ceramics through metallization and brazing techniques.

Alumina can be processed in green billets, billets or in a completely dense state. In the green or billet state, alumina can be processed into complex geometric shapes relatively easily. However, in order to fully densify the material, the sintering process will cause the alumina green body to shrink by approximately 20%. This shrinkage means that when processing alumina before sintering, very strict tolerances cannot be maintained. To achieve very strict tolerances, diamond tools must be used to process/grind fully sintered materials. During this manufacturing process, very precise diamond-coated tools/grinding wheels are needed to grind the material until the desired shape is formed. Due to the inherent toughness and hardness of the material, this can be a time-consuming and costly process.

Product application

Alumina is a very hard ceramic with excellent wear resistance, making it an ideal material for manufacturing wear-resistant blades or products. It is usually used as a high-temperature electrical insulator, especially for alumina with higher purity, which has a higher resistivity. It can also withstand strong acids and alkalis at high temperatures, making it highly suitable for applications that require corrosion resistance.

Classified by purity

Electrical performance

Classify by color

Forming method

Sutech has 5 molding techniques: dry pressing, high pressure injection olding, low pressure injection molding, Isostatic pressing molding, gel casting molding.In accord with customers specific structure, size, accuracy and quantity requirements, we choose suitable molding technique.

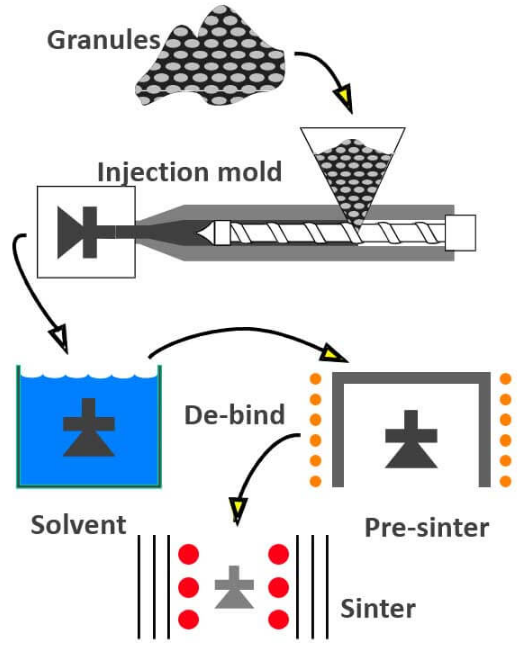

- Injection Molding+

The injection molding process involves mixing fine alumina powder with a binder to create a feedstock, which is then heated to form a viscous slurry. This slurry is injected into a mold to form a green body (pre-sintered part). After molding, the binder is removed, and the part is sintered to achieve full densification, resulting in the final ceramic product.

The injection molding process involves mixing fine alumina powder with a binder to create a feedstock, which is then heated to form a viscous slurry. This slurry is injected into a mold to form a green body (pre-sintered part). After molding, the binder is removed, and the part is sintered to achieve full densification, resulting in the final ceramic product. - Extrusion Molding+

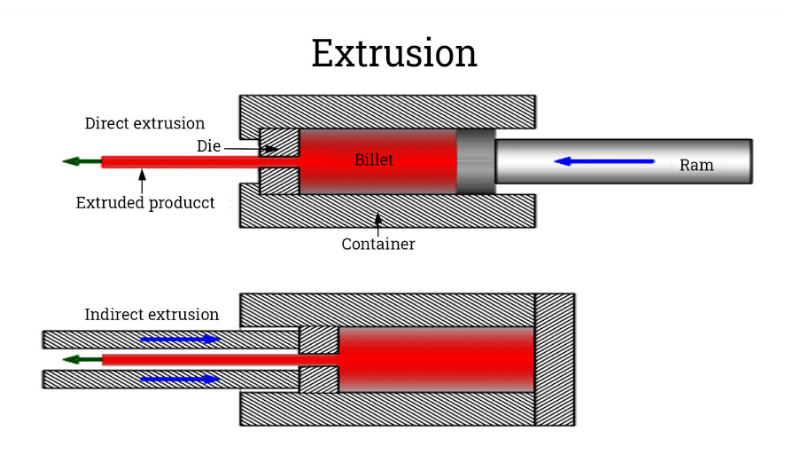

Extrusion molding involves forcing a dough-like feedstock through a die under pressure to form the desired shape. The binder in the mixture helps maintain the form during the drying process.

Extrusion molding involves forcing a dough-like feedstock through a die under pressure to form the desired shape. The binder in the mixture helps maintain the form during the drying process. - Isostatic Pressing+Isostatic pressing can be performed using either wet-bag or dry-bag techniques. In this process, spray-dried powder is encapsulated in a rubber or polyurethane bag and subjected to uniform isostatic pressure. Wet-bag pressing is typically used for producing simple shapes, while dry-bag pressing is suitable for forming more complex geometries.

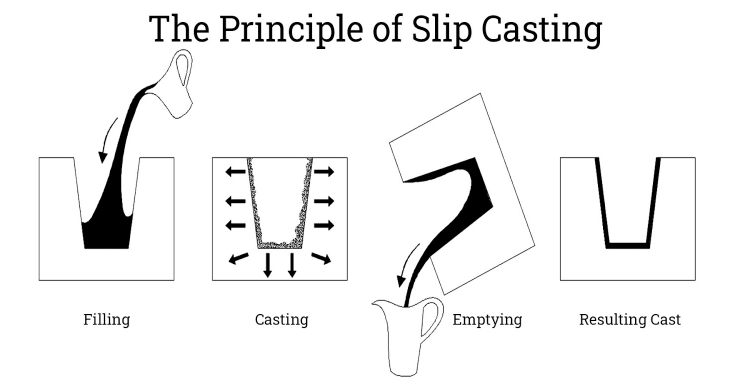

- Slip Casting+

Slip casting, also known as drain casting, involves pouring a liquid water-based ceramic slurry into a porous plastic mold. Water is drawn out of the slurry, leaving a layer of solidified powder on the inner surface of the mold. As the thickness of the cast increases, the excess slurry is removed. In pressure casting, additional pressure is applied to the slurry to produce thicker and stronger components.

Slip casting, also known as drain casting, involves pouring a liquid water-based ceramic slurry into a porous plastic mold. Water is drawn out of the slurry, leaving a layer of solidified powder on the inner surface of the mold. As the thickness of the cast increases, the excess slurry is removed. In pressure casting, additional pressure is applied to the slurry to produce thicker and stronger components.