QualityCenter

Machining Center

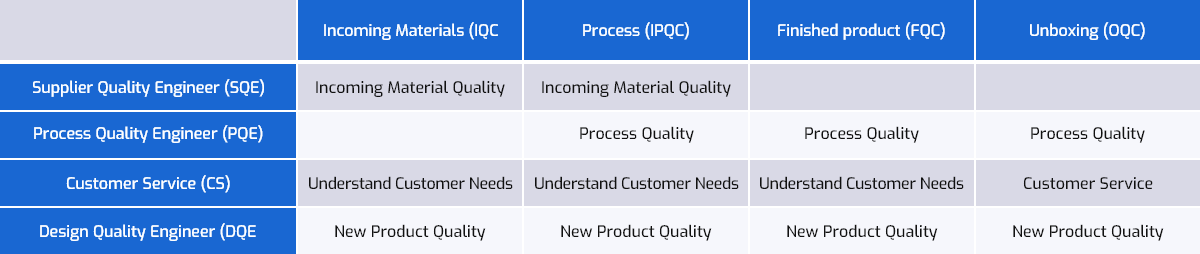

The Quality Department consists of process quality engineers, incoming material inspection, process inspection, final product inspection, unboxing inspection, design engineers, and customer service functional modules. Their respective responsibilities are as follows:

- 1. Process quality engineer: Responsible for the analysis of non-conforming products and promoting improvement, including quality projects, handling customer complaints, quality control for new product introduction, product quality maintenance, and product certification, etc.

- 2. Incoming Material Inspection & Supplier Quality Engineer: Responsible for the incoming inspection of all production materials purchased by the company and the management of the company’s suppliers.

- 3. Process inspection: Responsible for the process inspection and control work in each production workshop of the company, including the first inspection of each process, patrol inspection, testing, and auditing.

- 4. Final inspection of finished products: Be responsible for the final inspection of all products of the company and the inspection of product CSL-1.

- 5. Unpacking inspection: Responsible for the shipment inspection of all company products and the inspection of returned products, and assist customer service in completing customer-related work.

QualityCenter

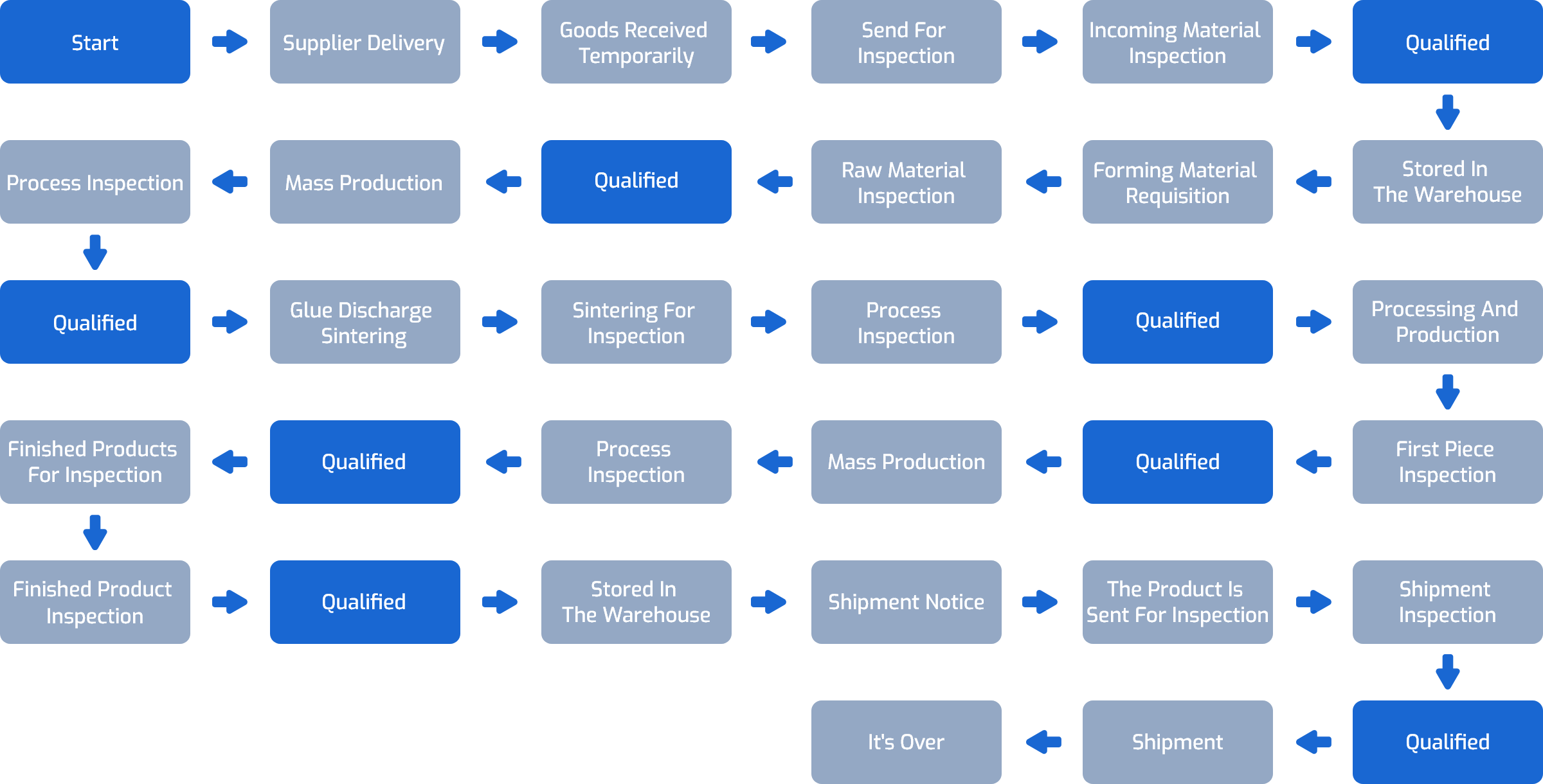

Quality supervision process

QualityCenter

Quality supervision process

Raw material inspection

Process detection

Finished product inspection

Raw material inspection

Process detection

Finished product inspection