Aluminum Nitride

Aluminum Nitride

Aluminum nitride (AlN) is a non-oxide ceramic material mainly composed of aluminum and nitrogen (Al -65.81%, N-34.19), with the chemical formula AlN. It is a solid aluminum nitride with a thermal conductivity as high as 321 W and is also an excellent electrical insulator. The band gap of the aluminum nitride wurtzite phase at room temperature is approximately 6 eV. Due to these characteristics, this ceramic has been proven to be applicable in a variety of applications, such as optoelectronic devices operating at deep ultraviolet frequencies.

Material Advantages

- High thermal conductivity (above 170W/mK). This value is close to that of BeO and SiC, and is more than five times that of alumina (Al2O3).

- Its coefficient of thermal expansion is 4.5 × 10-6℃, the same as that of silicon (3.5 × 4 × 10-6℃).

- It has good light transmission characteristics

- It is not toxic.

- It has excellent electrical conductivity. The electrical properties of aluminum nitride include its dielectric constant, dielectric loss, bulk resistivity and dielectric strength – all these characteristics make it an excellent insulating material.

- Excellent mechanical properties: The mechanical properties of aluminium also make it widely used in industrial processes. Its flexural strength is higher than that of alumina (Al2O3) and beryllium oxide (BeO) ceramics.

Material grade

PCAN1000

PCAN2000

PCAN3000

PCAN1000S Substrate

Overview

PCAN1000 is our standard high purity aluminium nitride with a thermal conductivity of 170 W/mK. This is the same thermal performance as our substrate material but offers the possibility of larger pieces in length/width and in thicknesses up to 30mm.

PCAN1000 has good coefficient of thermal expansion – matched to silicon and gallium nitride over wide temperature ranges.

PCAN1000 has good coefficient of thermal expansion – matched to silicon and gallium nitride over wide temperature ranges.

Applications

- High power insulators

- Laser components

- Water cooled heatsinks

- Power electronics

- Aerospace, medical and semiconductor components supplied to ISO9001/2015

Overview

PCAN2000 is one of our enhanced grades of aluminium nitride, offering all the mechanical performance of PCAN1000 with the enhanced benefits of 200 W/mK thermal conductance.

Applications

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers supplied to ISO9001/2015

Overview

PCAN3000 is one of our enhanced grades of aluminium nitride offering, all the mechanical performance of PCAN1000 with the enhanced benefits of 230 W/mK thermal conductance.

Applications

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers supplied to ISO9001/2015

Overview

PCAN1000S 170 W/mK is our standard high thermal conductivity substrate material, However, other high-performance grades are also available.

Applications

- Heat sinks

- Heat spreaders

- Laser heatsinks power rectifiers

- Aerospace, power electronics, rectifiers supplied to ISO9001/2015

Aluminum Nitride Material Properties

Mechanical Properties

Thermal Properties

Electrical Properties

| Property | Unit | PCAN1000 | PCAN2000 | PCAN3000 | PCAN1000S |

|---|---|---|---|---|---|

| Density | g/cm3 | 3.32 | 3.32 | 3.32 | 3.30 |

| Young’s Modulus | GPa | 300-350 | 300-350 | 300-350 | 350 |

| Fracture Toughness KIC | MPa m1/2 | 3 | 3 | 3 | 3 |

| Poisson’s Ratio | – | 0.22 | 0.22 | 0.22 | 0.22 |

| Compressive Strength | MPa | 3000 | 3000 | 3000 | 3000 |

| Flexural Strength @ 25°C | MPa | 350 | 350 | 350 | 350 |

| Hardness | GPa | 10 | 10 | 10 | 11 |

| Property | Unit | PCAN1000 | PCAN2000 | PCAN3000 | PCAN1000S |

|---|---|---|---|---|---|

| Thermal Conductivity @ 25°C | W/mK | 170 | 200 | 230 | 170 |

| * CTE 25°C ➞ 400°C | 10-6/K | 4.5 | 4.5 | 4.5 | 4.6 |

| ** Max Temperature (Air) | °C | 1200 | 1200 | 1200 | 1200 |

| ** Max Temperature (Inert) | °C | 1200 | 1200 | 1200 | 1200 |

Coefficient of Thermal Expansion (CTE) describes how the size of an object changes with a change in temperature.

** Note: No Load

Note: AlN can form a surface Aluminum oxide layer. This helps to protect the material, however, it impacts the thermal conductivity (Alumina is ~30 W/mK). In oxidizing atmospheres, this layer develops around 700°C. In inert atmospheres, this layer protects the AlN up to ~1350°C. Bulk oxidation will occur at temperatures above this.

| Property | Unit | PCAN1000 | PCAN2000 | PCAN3000 | PCAN1000S |

|---|---|---|---|---|---|

| Dielectric Constant | 1 MHz | 8.8 | 8.8 | 8.5 | 8.8 |

| Dielectric Loss | 1 MHz | 5×10-4 | 5×10-4 | 5×10-4 | 5×10-4 |

| Dielectric Strength DC @ 25°C | kV/mm | 15 | 15 | 15 | 14 |

| Volume Resistivity @ 25°C | ohm-cm | >1013 | >1013 | >1013 | >1014 |

Disclaimer: The values presented are mean and typical of those resulted from test samples. They are provided as an indication only to serve as guidance in the design of ceramic components and are not guaranteed in any way. The actual values can vary according to the shape and size of the envisioned component.

Aluminum Nitride Machining

Aluminum nitride can be processed in a green, billet, or fully dense state. When in the state of raw or billet, it can be relatively easily processed into complex geometric shapes. However, in order to fully densify the material, the sintering process causes the aluminum nitride billet to shrink by about 20%. This shrinkage means that very strict tolerances cannot be maintained when processing aluminum nitride before sintering.

In order to achieve very strict tolerances, diamond tools must be used to process/grind fully sintered materials. During this process, very precise diamond coated tools/grinding wheels are required to grind the material until the desired shape is achieved. Due to the inherent toughness and hardness of the material, this process may be time-consuming and costly.

In order to achieve very strict tolerances, diamond tools must be used to process/grind fully sintered materials. During this process, very precise diamond coated tools/grinding wheels are required to grind the material until the desired shape is achieved. Due to the inherent toughness and hardness of the material, this process may be time-consuming and costly.

Product application

Aluminum Nitride is one of the few materials that offers electrical insulation and high thermal conductivity. This makes AlN extremely useful in high power electronic applications in heat sink and heat spreader applications. Other materials that are commonly used are boron nitride, Shapal Hi-M Soft, beryllium oxide, and sometimes alumina.

Classified by purity

Electrical performance

Classify by color

Forming method

Aluminum nitride (AlN) is a non-oxide ceramic material mainly composed of aluminum and nitrogen (Al -65.81%, N-34.19), with the chemical formula AlN. It is a solid aluminum nitride with a thermal conductivity as high as 321 W and is also an excellent electrical insulator. The band gap of the aluminum nitride wurtzite phase at room temperature is approximately 6 eV. Due to these characteristics, this ceramic has been proven to be applicable in a variety of applications, such as optoelectronic devices operating at deep ultraviolet frequencies.

- Casting molding method+

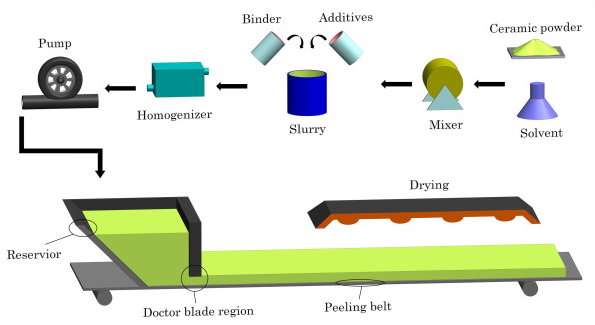

Casting molding is a very important process for forming ceramic substrates. AlN powder is uniformly mixed with a composite binder (consisting of a dispersant, solvent, binder and plasticizer) to obtain AlN casting slurry. After degassing and other processes, the slurry is poured into the hopper. After being smoothed by a scraper, a thin layer of uniform thickness and smooth surface is formed on the smooth strip-shaped surface. After drying, a green body with good toughness is prepared. After degreasing and sintering, the AlN substrate material is obtained. This process is mostly used for manufacturing aluminum nitride ceramic plates or substrates.

Casting molding is a very important process for forming ceramic substrates. AlN powder is uniformly mixed with a composite binder (consisting of a dispersant, solvent, binder and plasticizer) to obtain AlN casting slurry. After degassing and other processes, the slurry is poured into the hopper. After being smoothed by a scraper, a thin layer of uniform thickness and smooth surface is formed on the smooth strip-shaped surface. After drying, a green body with good toughness is prepared. After degreasing and sintering, the AlN substrate material is obtained. This process is mostly used for manufacturing aluminum nitride ceramic plates or substrates. - Dry pressing molding+

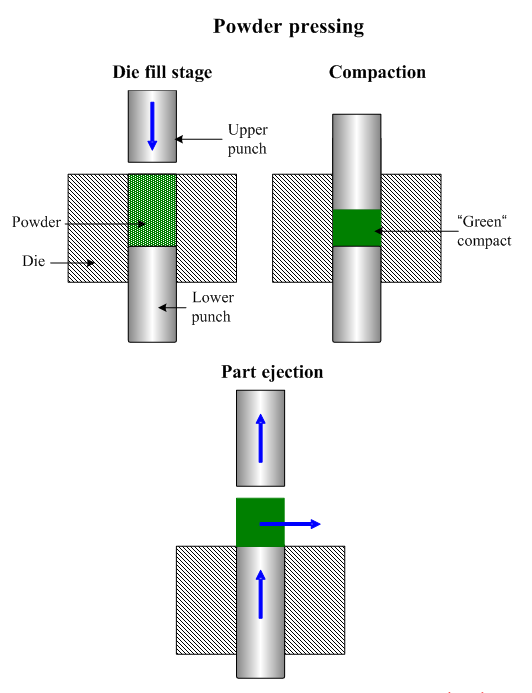

Dry pressing forming is a process in which AlN powder modified and pre-treated with surfactants is added to a metal mold, and pressure is slowly applied to form a dense blank. In essence, it relies on external pressure and the interaction between AlN powder particles to maintain a certain shape and high density of the green body. It is beneficial to the sintering of ceramics, can lower the sintering temperature and increase the density of ceramics.

Dry pressing forming is a process in which AlN powder modified and pre-treated with surfactants is added to a metal mold, and pressure is slowly applied to form a dense blank. In essence, it relies on external pressure and the interaction between AlN powder particles to maintain a certain shape and high density of the green body. It is beneficial to the sintering of ceramics, can lower the sintering temperature and increase the density of ceramics. - Injection molding+

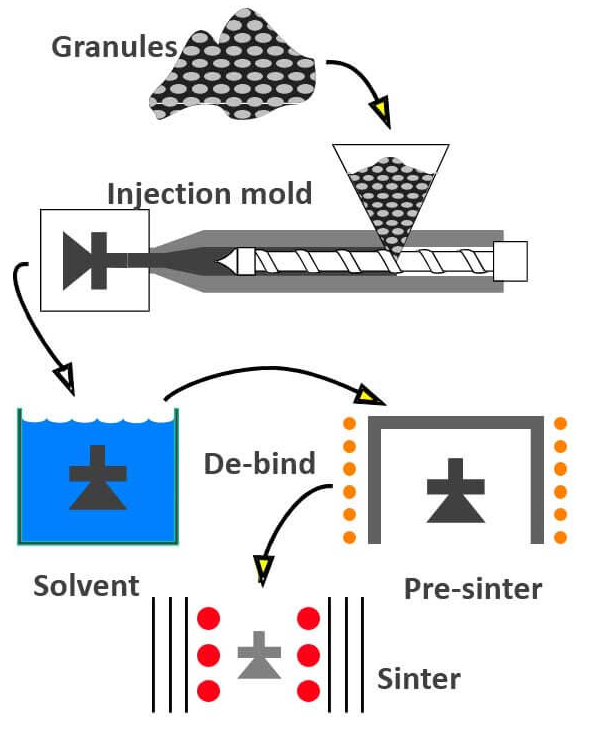

Through injection molding technology, the problems of high hardness, brittleness and difficult processing of aluminum nitride ceramics have been effectively solved. The precision manufacturing of various micro-complex-shaped and high thermal conductivity aluminum nitride products has been successfully achieved. Especially for small-sized and complex-shaped aluminum ceramic parts, efficient production has been realized, saving raw material and mechanical processing costs and improving production efficiency.

Through injection molding technology, the problems of high hardness, brittleness and difficult processing of aluminum nitride ceramics have been effectively solved. The precision manufacturing of various micro-complex-shaped and high thermal conductivity aluminum nitride products has been successfully achieved. Especially for small-sized and complex-shaped aluminum ceramic parts, efficient production has been realized, saving raw material and mechanical processing costs and improving production efficiency.