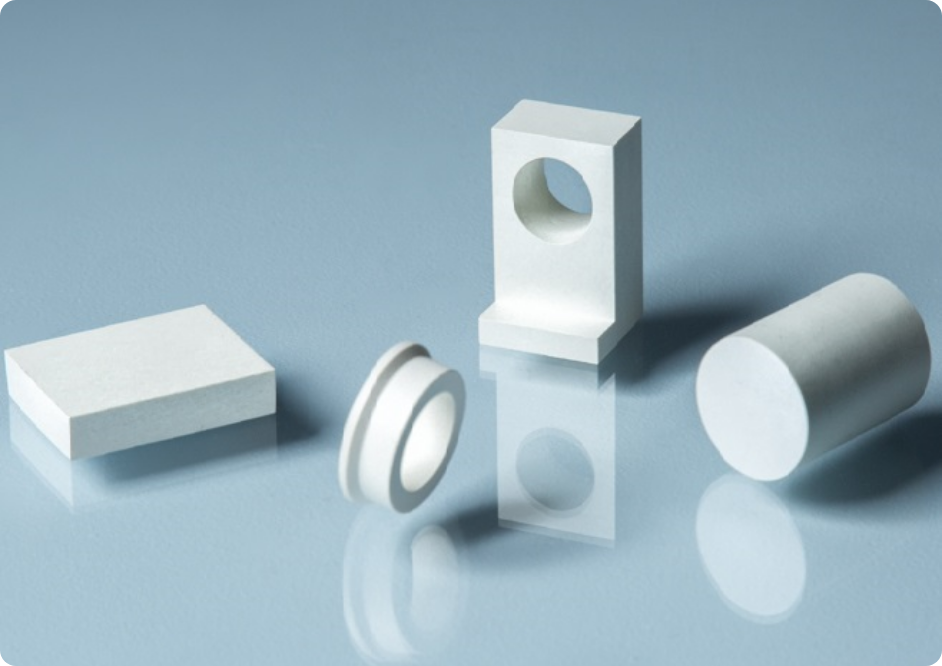

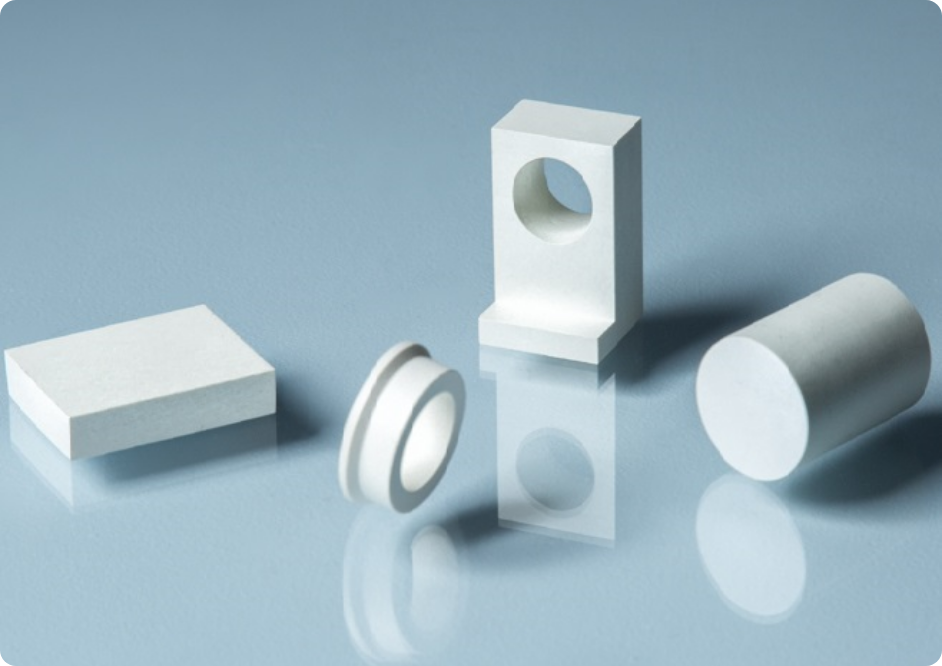

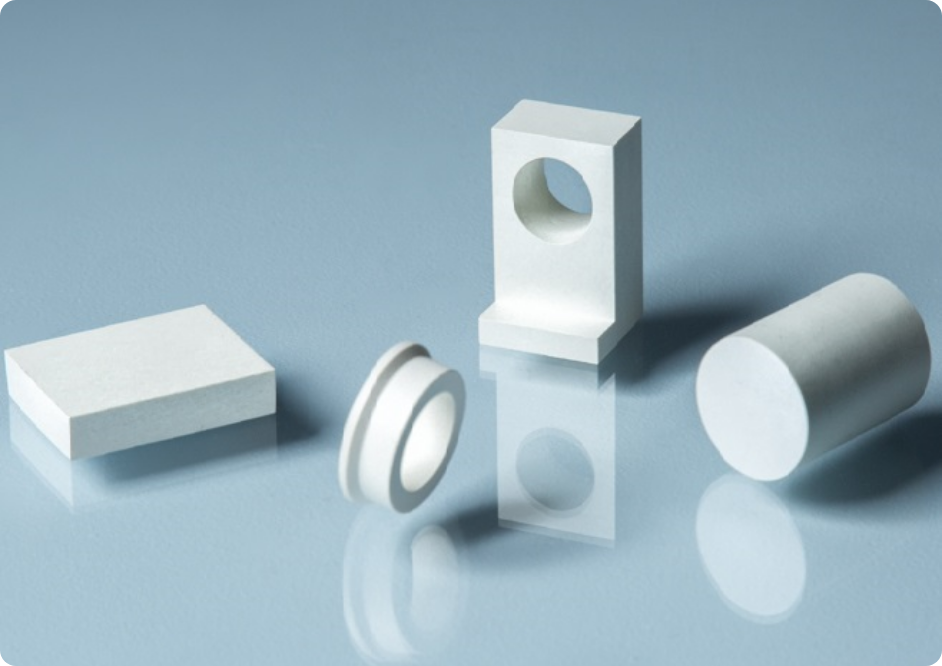

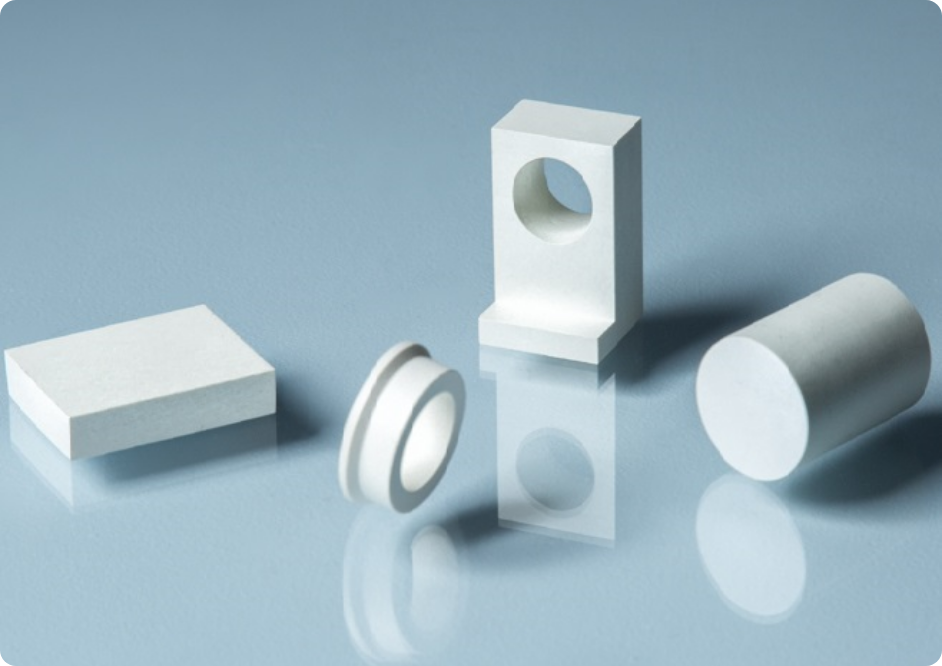

classify by shape

Spherical Components

Disc

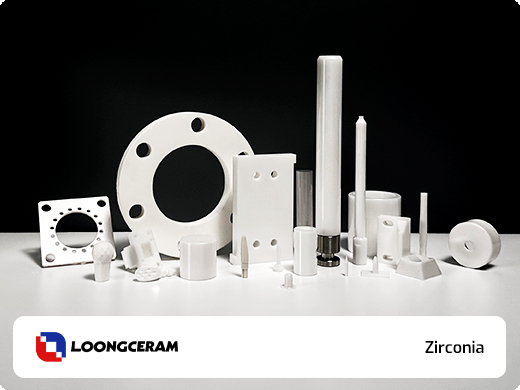

Custom Parts

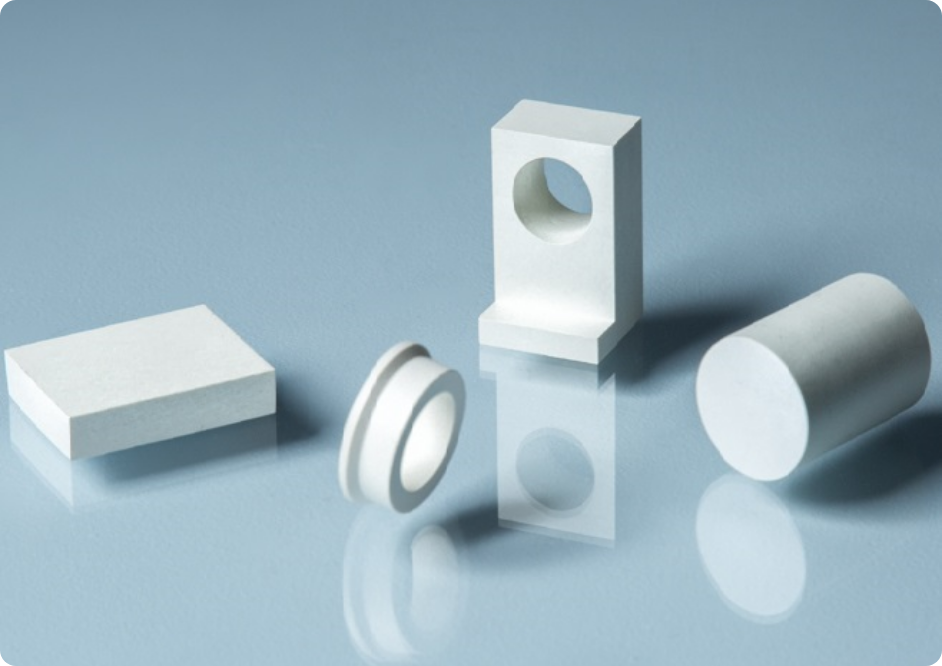

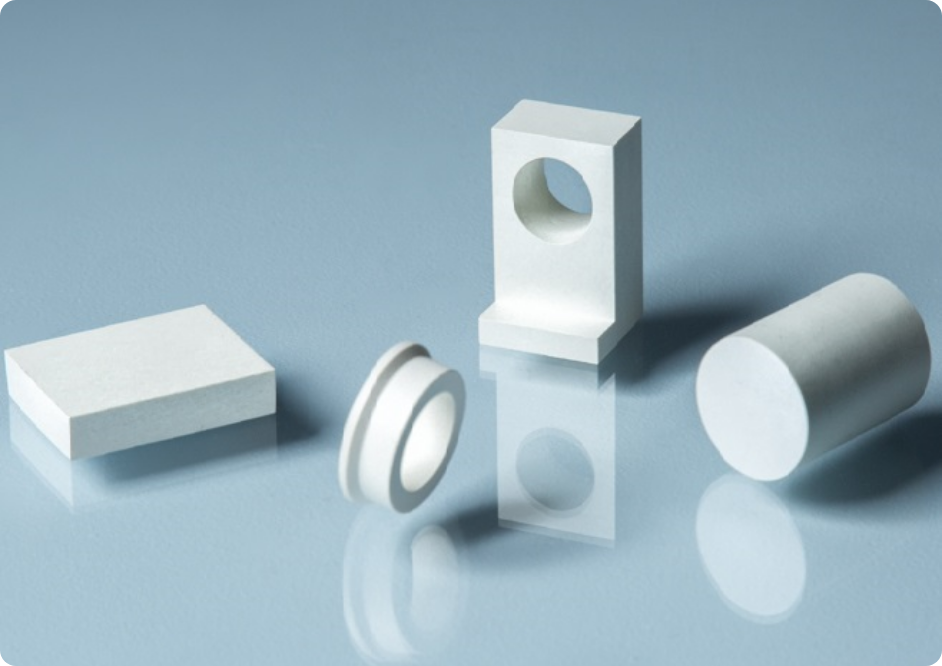

Block

Rod

Tube

Spherical Components

The cold isostatic pressing (CIP) forming process is adopted with a pressure range of 100-350 MPa. The resin removal and sintering processes are precisely controlled (prepared at 1600-1700°C, followed by densification treatment at 150-200 MPa and 1400-1600°C). Through precise machining processes, strict control is applied to the product’s surface finish (Ra: less than 0.01 microns) and dimensional tolerance (sphericity: 0.005 mm).

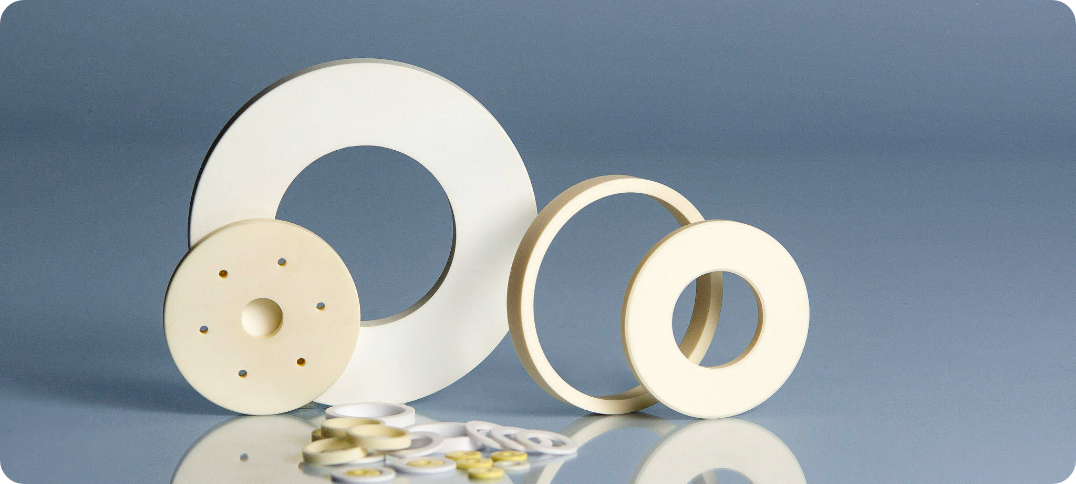

Disc

Using dry pressing (100–300 MPa) with precise debinding and sintering control, followed by precision machining to strictly ensure surface roughness (Ra: 0.01–0.8μm, controllable) and dimensional tolerances (parallelism: 0.005mm; flatness: 0.010mm).

Custom Parts

Establishing a binder system with low viscosity, high fluidity, and high stability, adopting low-pressure/high-pressure injection molding (100–200 MPa), followed by precise debinding and sintering at 1500–1700 °C, and precision grinding and polishing processes to strictly control surface finish and tolerances.

Block

Using dry pressing (100–300 MPa) with precise debinding and sintering control, followed by precision machining to strictly ensure surface roughness (Ra: 0.01–0.8μm, controllable) and dimensional tolerances (parallelism: 0.005mm; flatness: 0.010mm).

Rod

Manufactured by dry/wet cold isostatic pressing (100–350 MPa), with precise debinding and special sintering (1600–1700 °C), followed by precision machining to ensure strict control of surface roughness (Ra < 0.01 µm) and dimensional tolerance (cylindricity: 0.005 mm).

Tube

Manufactured by dry/wet cold isostatic pressing (100–350 MPa), with precise debinding and special sintering (1600–1700 °C), followed by precision machining to ensure strict control of surface roughness (Ra < 0.01 µm) and dimensional tolerance (cylindricity: 0.005 mm).

Why choose us?

Longci Has Always Been Driven By Technological Innovation, Building A Full-Chain Capability From R&D To Production, And Providing Customers With One-Stop Solutions. With The Core Advantages Of Precise And Controllable Cost Optimization, Efficient And Stable Delivery Guarantee, And Outstanding Quality Under Strict Standards, It Has Become A Trusted Partner In The Industry.

Product Search by Industries

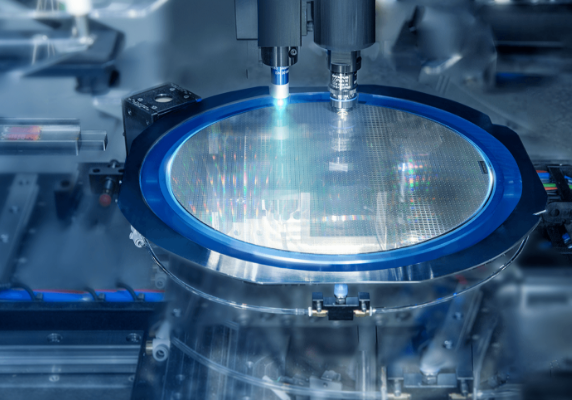

Semiconductor Manufacturing

Wafer processing, photolithography, etching, deposition equipment, etc

aerospace

Ceramic Matrix Composites (CMC) High-Temperature Ceramics Thermal Protection Systems (TPS) Ablative Materials Engine Components (e.g., nozzles, turbine blades) Ceramic Bearings Piezoelectric Sensors Thermal Insulation Materials Radar Absorbing Materials (RAM) Ceramic Coatings (e.g., for hot gas path components) Radiation Protection Materials Ceramic Fuel Cells

consumer-family

Ceramic Cookware Ceramic Water Filters Ceramic Tile Ceramic Knives Ceramic Heat Insulation Materials Ceramic Water Softening Systems Ceramic Dental Implants Ceramic Heating Elements Ceramic Bathware Ceramic Electrical Insulators Ceramic Mugs and Tableware Ceramic Storage Containers Ceramic Sensors Ceramic Decorative Items Ceramic Air Purifiers

Medical Equipment

Implanted devices, medical equipment, etc.

Environment/Energy

Liquid hydrogen, batteries, incinerators, heat dissipation, etc

Industrial Manufacturing

Thick film substrates, thin film substrates, etc.

Automobile Industry

Molten aluminium, ferrite, pressure sensors, etc.

food and agriculture

Feedthrough components, insulating joints, ceramic cavities, etc.

ABOUT LOONGERAM

Advanced ceramics bring new value to the world

Since 2013, Loongeram has provided high-quality ceramic products and services to hundreds of companies around the world and manufactured more than 5,000 advanced technical ceramic parts.

laboratory

Have a professional R & D team

service

Friendly cooperation with customers

Advanced precision ceramics bring value to the world

5000+

Product Category

30+

Countries & Regions

11Yr

Manufacturing Exp

Our Latest Blog

Ceramic bearing balls: standards for accuracy and strength

This article provides a detailed technical analysis of the Adesto Technologies …

Compressive strength of ceramic bearing ball

This article provides a detailed technical analysis of the Adesto Technologies …

Compressive strength of ceramic bearing ball

This article provides a detailed technical analysis of the Adesto Technologies …

Request A Quote

INFORMATION

WhatsApp:+852 5172 2979 ;WhatsApp:+852 5105 9433

ashleygao@loongceram.com

1505, Block A, Building 1, Shangzhi Technology Park, 380 Guangming Avenue, Tangwei Community, Fenghuang Street, Guangming District, Shenzhen