OURService

Machining Center

The machining center was established in 2014, dedicated to the processing of special ceramic parts. With over ten years of experience in processing materials such as alumina, zirconia, silicon carbide, silicon nitride, and aluminum nitride, it can achieve ultra-high dimensional accuracy, flatness, cylindricity, and surface finish. It can provide customers with the most cost-effective processing technology solutions.

50+

3-5 axis precision machining equipment

40+

Detection instrument

5000+

Processing base

50+

Technical talent reserve resources

Super-brittle andhard material

Ultra-precision processing capability

Ceramic flexible processing

For products with complex structures, setting programs for automatic processing can well control the processing accuracy and positional degree. The processing accuracy can reach 0.008MM, and the surface roughness can reach Ra0.4μm

Ceramic micro-hole processing

For special products of ceramic with ultra-high precision and tiny holes, automatic processing of small holes is carried out to precisely control the size and roundness. The processing diameter ranges from 0.021 to 0.06mm, with a diameter accuracy of 0.002mm, a concentricity of 0.005mm, and a surface roughness of up to 0.2μm

The surface of the alloy is precisely mirror-polished

Precision polishing of small-sized alloy planes can achieve a surface roughness of Ra0.02um and a flatness of 0.005MM

Process high-precision planes

The Processing Flatness Of A 4-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of A 6-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of An 8-Inch Diameter Can Reach 0.005MM.

The Flatness Of A 12-Inch Diameter Processing Can Reach 0.005 To 0.010MM

The Processing Flatness Of A 6-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of An 8-Inch Diameter Can Reach 0.005MM.

The Flatness Of A 12-Inch Diameter Processing Can Reach 0.005 To 0.010MM

Material research anddevelopment capability

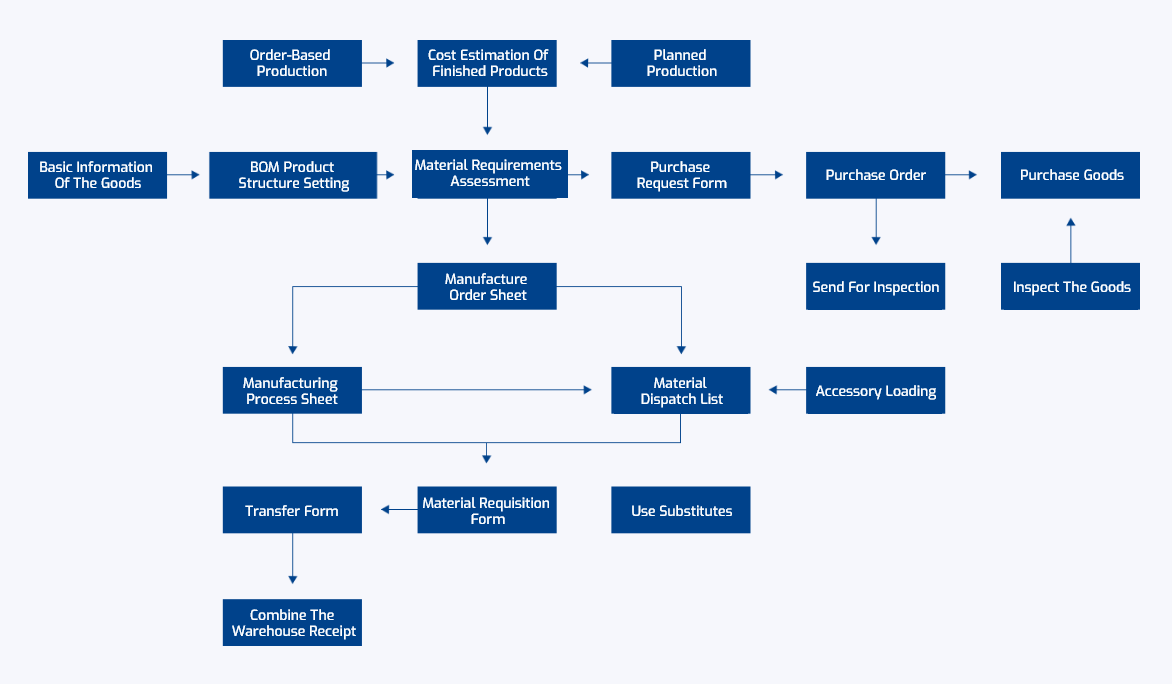

PC/MC operation mode

(production control) The most important task of a production control system is first and foremost to control the basic inventory and flow inventory, that is, to balance the input and output. Then use the method of precise control to reduce the controlled inventory. At the same time, some measures of capacity planning and batch planning can also be considered.

Material Control is the supervision and management process of the application, receipt, issuance and use of materials based on the material plan.

Material Control is the supervision and management process of the application, receipt, issuance and use of materials based on the material plan.

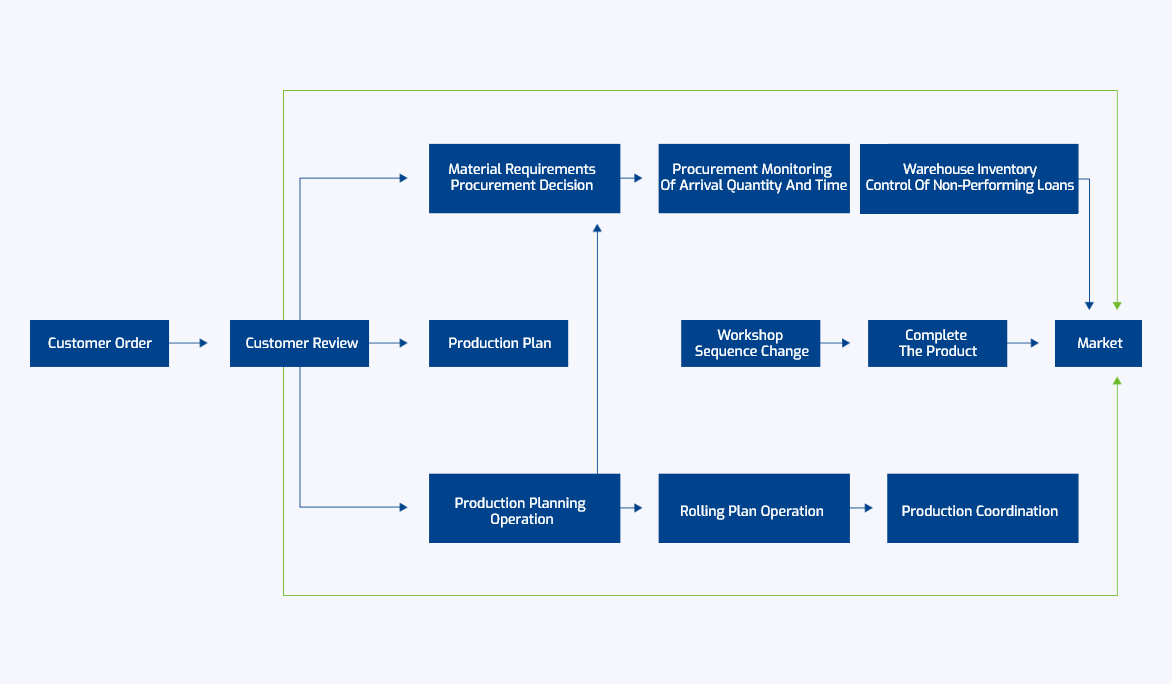

Material research anddevelopment capability

- Special Technical Reserve+It Can Be Applied To Various Types Of Process And Production Control. It Enables You To Trace The Following Information About The Product: Which Part Was Installed In The Finished Product? What Key Parameters That Need To Be Controlled Are Generated During The Product Production Process, And Are They All Qualified? And The Strict Control Over The Current Manufacturing Process, Etc.

The Task Of The Traceability System Is To Ensure That The Specified Parts Are Installed On The Designated Products To Achieve The Required Performance Of The Products And Minimize The Risk Of Recalled Products, Which Is Directly Related To Manufacturing Costs. - Confidentiality Mechanism+