Flexural strengthStrength

What is Flexural Strength?

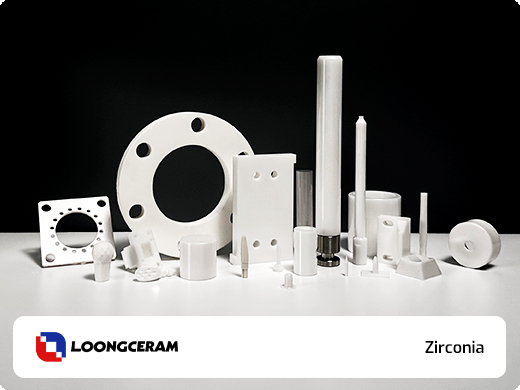

Flexural strength, also known as bending strength, modulus of rupture, or transverse rupture strength, is the maximum stress that a material can withstand before failing in a bending test.Advanced ceramics exhibit a range of flexural strengths depending on the ceramic material tested. The range is broad and materials based on Zirconia, ATZ or Silicon Nitride compositions exhibit relatively high bending strengths. Unlike metals, which deform before breaking, ceramics are purely elastic in nature and will fracture upon reaching their maximum yield.

Materials Ranked by Flexural Strength

CeramAlox™ Ultra Pure’s compressive strength performance characteristics are the highest compared to all other materials. This is closely followed by Zirconia Toughened Alumina, Silicon Carbide, and Silicon Nitride and others.

Related Properties

Hardness

One of the most valuable characteristics of advanced ceramics in high-performance applications is their extreme hardness. Hard ceramic materials are used for a wide range of applications in diverse fields and applications such as cutting tools for milling and grinding.

Compressive strength

Compressive strength is the capacity of a material to withstand loadstending to reduce size. Explained differently, compressive strength resistscompression (being pushed together), whereas tensile strength resiststension (being pulled apart).

Fracture Toughness

The ability to resist fracture is a mechanical property of materials knownas fracture toughness. For advanced ceramics it uses a critical stressintensity factor known as KlC where the fracture normally occurs at thecrack terminations.