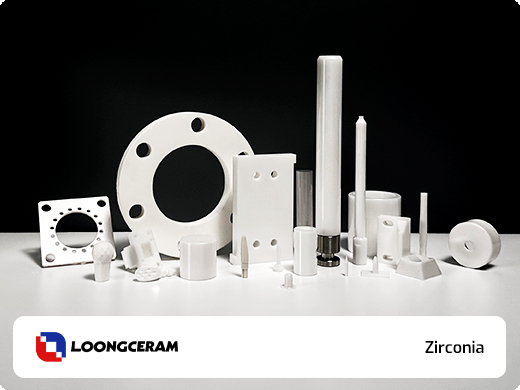

Zirconia

Zirconia (ZrO2)

Zirconia ceramics, also known as zirconium dioxide ceramics, are exceptionally strong industrial ceramic materials.

They offer outstanding hardness, toughness, and corrosion resistance—without the typical brittleness found in other ceramics. Zirconia ceramics are available in several grades, with the most common being partially stabilized zirconia (PSZ) using yttria (Y₂O₃) or magnesia (MgO) as stabilizers.

They offer outstanding hardness, toughness, and corrosion resistance—without the typical brittleness found in other ceramics. Zirconia ceramics are available in several grades, with the most common being partially stabilized zirconia (PSZ) using yttria (Y₂O₃) or magnesia (MgO) as stabilizers.

Material Advantages

- Use temperatures up to 1000°C

- Low thermal conductivity

- Chemical inertness

- Resistance to molten metals

- Wear resistance

- High fracture toughness

- High hardness

Material grade

Ultra Tough

Ultra Tough HIP

3YZ

Nano HIP

Overview

CeramaZirc Ultra Tough is a advanced zirconia ceramic composite material based on partially stabilized zirconia and an enhanced crystal structure.

CeramAlox 96 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

General Properties

CeramAlox 96 can be machined in the “green state”- that is before sintering takes place, thus ensuring a large variety of shapes and sizes. CeramAlox 96 can also be diamond ground to tight tolerances in the fully sintered state using diamond grinding.

General Properties

- Use temperatures up to 1500°C

- Sintered to full density for a pore-free structure and competitive price

- No compromise between bending strength, hardness, and fracture toughness

- Remarkably high fracture toughness and impact resistance while maintaining above average values for bending strength and hardness

- Toughening by crack deflection provided by a unique microstructure in a partially stabilized zirconia matrix

- Increased resistance to hydrothermal aging through Ceria partial stabilization

Applications

- High pressure equipment ball valve balls and seats – particularly suitable for applications where mechanical shock, impacts, or vibrations are present

- Ultra high pressure pumping elements

- Flow control devices for ultra-high pressure equipment – stems and seats for high pressure homogenisers

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

Overview

CeramaZirc Ultra Tough HIP is an advanced zirconia ceramic composite material based on partially stabilized zirconia and an enhanced crystal structure. It is the latest and toughest composite to be introduced by Precision Ceramics.

General Properties

General Properties

- Use temperatures up to 1500°C

- Hot isostatically pressed (HIP’ed) for superior strength and reliability

- No compromise between bending strength, hardness and fracture toughness

- Remarkably high fracture toughness and impact resistance while maintaining above average values for bending strength and hardness

- Toughening by crack deflection provided by a unique microstructure in a partially stabilised zirconia matrix

- Increased resistance to hydrothermal aging through Ceria partial stabilization

Applications

- High pressure equipment ball valve balls and seats – particularly suitable for applications where mechanical shock, impacts, or vibrations are present

- Ultra high pressure pumping elements

- Flow control devices for ultra-high pressure equipment – stems and seats for high pressure homogenizers

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

Overview

High purity 3 mol % Yttria Partially Stabilized Zirconia (3YSZ) has a finer grain structure that ensures higher mechanical properties. Increased grain size uniformity ensures better isotropy of properties.

General Properties

General Properties

- Use temperatures up to 1000°C

- Low thermal conductivity

- Chemical inertness

- Resistance to molten metals

- Wear resistance

- High fracture toughness

- High hardness

Applications

- High pressure equipment ball valve balls and seats – particularly suitable for applications where mechanical shock, impacts, or vibrations are present

- Ultra high pressure pumping elements

- Flow control devices for ultra-high pressure equipment – stems and seats for high pressure homogenizers

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

Overview

Highest purity 3 mol % Yttria Partially Stabilized Zirconia (3YSZ) with ultrafine grain structure ensures exceptional performance. Densified to full theoretical density through Hot Isostatic Pressing (HIP) for outstanding reliability.

General Properties

General Properties

- Use temperatures up to 1000°C

- Low thermal conductivity

- Chemical inertness

- Resistance to molten metals

- Wear resistance

- High fracture toughness

- High hardness

Applications

- High pressure equipment ball valve balls and seats – particularly suitable for applications where mechanical shock, impacts, or vibrations are present

- Ultra high pressure pumping elements

- Flow control devices for ultra-high pressure equipment – stems and seats for high pressure homogenisers

- Deep well down-hole valves and seats

- Rollers and guides for metal forming

Material Properties

Mechanical Properties

Thermal Properties

Electrical Properties

| Property | Unit | Ultra Tough | Ultra Tough HIP | 3YZ | Nano HIP |

|---|---|---|---|---|---|

| Composition | – | Ceria Stabilized | Ceria Stabilized | Yttria Stabilized | Yttria Stabilized |

| Color | – | Grey | Brown / Orange | Ivory | Grey |

| Property | Unit | Ultra Tough | Ultra Tough HIP | 3YZ | Nano HIP |

|---|---|---|---|---|---|

| Density | g/cm3 | 5.7 | 5.7 | 6.05 | 6.07 |

| Young’s Modulus | GPa | 200 | 200 | 200 | 200 |

| Fracture Toughness KIC | MPa m1/2 | 17 | 17 | 8 | 8 |

| Poisson’s Ratio | – | 0.30 | 0.30 | 0.30 | 0.30 |

| Compressive Strength | MPa | 2000 | 2000 | 2000 | 2100 |

| Flexural Strength | MPa | 1000 | 1000 | 1200 | 1400 |

| Hardness | GPa | 13 | 13 | 13.5 | 14.5 |

1 No load

2 Coefficient of Thermal Expansion (CTE) describes how the size of an object changes with a change in temperature.

| Property | Unit | Ultra Tough | Ultra Tough HIP | 3YZ | Nano HIP |

|---|---|---|---|---|---|

| Maximum Temperature (Inert) 1 | °C | 1500 | 1500 | 1000 | 1000 |

| CTE2 25°C ➞ 400°C | 10-6/K | 10 | 10 | 10 | 10 |

| Thermal Conductivity @ 25°C | W/mK | 3 | 3 | 2 | 2 |

| Thermal Shock Resistance ΔT | °C | 250 | 250 | 250 | 250 |

Machining

Zirconia can be machined in green, biscuit, or fully dense states. While in the green or biscuit form, it can be machined relatively easily into complex geometries. However, the sintering process that is required to fully densify the material causes the zirconia body to shrink approximately 20%. This shrinkage means that it is impossible to hold very tight tolerances when machining zirconia pre-sintering.

In order to achieve very tight tolerances, the fully sintered material must be machined/ground with diamond tools. In this manufacturing process, a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherent toughness and hardness of the material, this can be a time consuming and costly process.

Precision Ceramics is your Zirconia machining specialist for your advanced ceramic prototyping & manufacturing needs. We use our many years of technical ceramics experience to provide advice on materials, design, and application. If you would like to buy zirconia plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

In order to achieve very tight tolerances, the fully sintered material must be machined/ground with diamond tools. In this manufacturing process, a very precise diamond coated tool/wheel is used to abrade away the material until the desired form is created. Due to the inherent toughness and hardness of the material, this can be a time consuming and costly process.

Precision Ceramics is your Zirconia machining specialist for your advanced ceramic prototyping & manufacturing needs. We use our many years of technical ceramics experience to provide advice on materials, design, and application. If you would like to buy zirconia plates, rods, tubes or custom machined components, please contact us and one of our experts will be happy to assist you.

Product application

Alumina is a very hard ceramic with excellent wear resistance, making it an ideal material for manufacturing wear-resistant blades or products. It is usually used as a high-temperature electrical insulator, especially for alumina with higher purity, which has a higher resistivity. It can also withstand strong acids and alkalis at high temperatures, making it highly suitable for applications that require corrosion resistance.

Classified by purity

Electrical performance

Classify by color

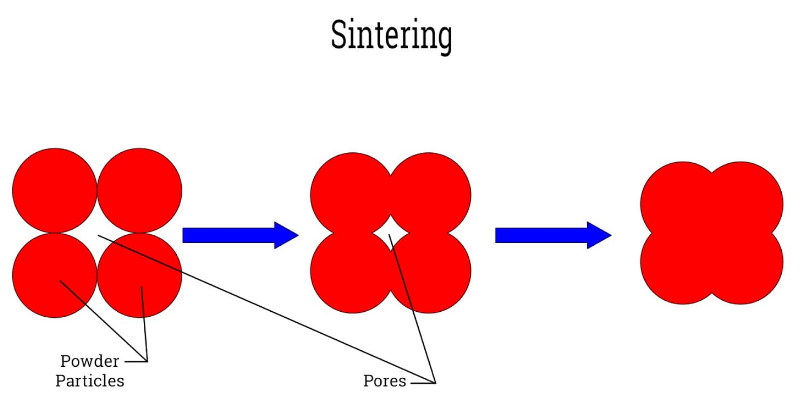

Sintering Process

- Sintering Process+

The sintering process plays a critical role in determining the quality and fabrication of zirconia ceramics. It involves heating stabilized zirconia powder to temperatures above 1000°C. Among the various sintering methods, pressureless sintering is the most commonly used. Sintering is a technique that heats the green body to a temperature below its melting point, allowing zirconia particles to diffuse and bond together, resulting in the densification and solidification of the ceramic powder.

The sintering process plays a critical role in determining the quality and fabrication of zirconia ceramics. It involves heating stabilized zirconia powder to temperatures above 1000°C. Among the various sintering methods, pressureless sintering is the most commonly used. Sintering is a technique that heats the green body to a temperature below its melting point, allowing zirconia particles to diffuse and bond together, resulting in the densification and solidification of the ceramic powder.