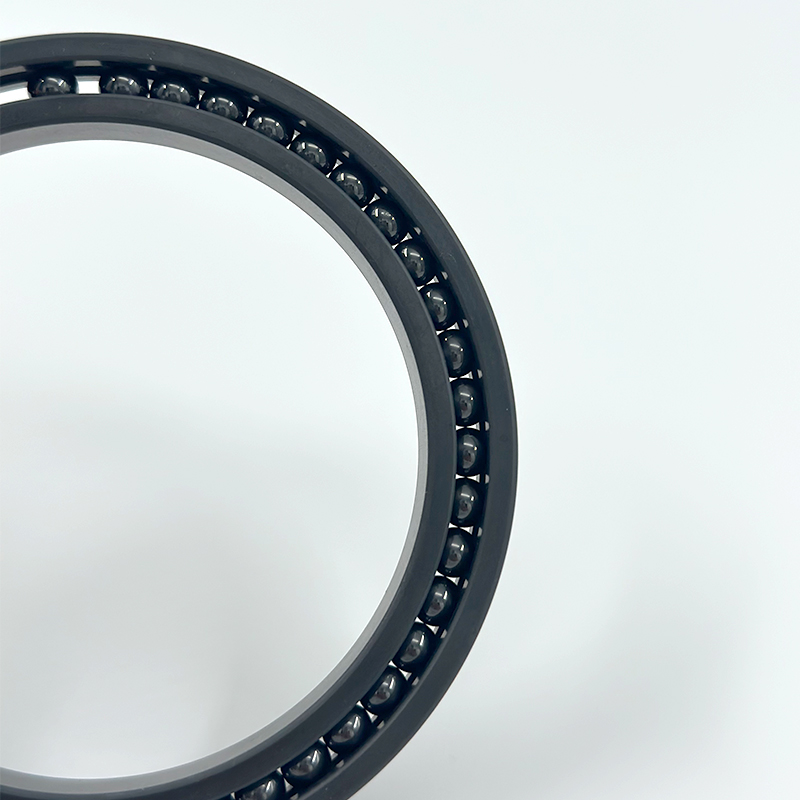

Silicon Carbide Ceramic Bearings

Ceramic bearings, with raceways and balls made entirely of ceramic material, are superior to ordinary steel bearings in many ways. Ceramics are ideal for any application that seeks higher speeds, reduced overall weight, or extreme harsh environments such as high temperatures and corrosive substances.

Ceramic bearings are typically made from the following materials:

Silicon Nitride (SiN4) | Aluminum Oxide (Al2O3) | Zirconium Oxide (ZrO2) | Silicon Carbide (SiC )

Because ceramics have a glass-like surface, the coefficient of friction is extremely low, making them well suited for applications that require reduced friction.

Ceramic balls require less lubrication and are harder than steel balls, which contributes to longer bearing life. Ceramic balls have better thermal properties than steel balls and therefore generate less heat at high speeds.

Silicon Nitride (SiN4) | Aluminum Oxide (Al2O3) | Zirconium Oxide (ZrO2) | Silicon Carbide (SiC )

Because ceramics have a glass-like surface, the coefficient of friction is extremely low, making them well suited for applications that require reduced friction.

Ceramic balls require less lubrication and are harder than steel balls, which contributes to longer bearing life. Ceramic balls have better thermal properties than steel balls and therefore generate less heat at high speeds.

Step 1

Product Features

- High hardness: Ceramic materials are harder than steel, increasing durability and minimizing wear.

- Low friction: Ceramic bearings have a lower coefficient of friction than steel bearings, which reduces energy consumption and increases efficiency.

- Lightweight: Ceramic materials are lighter than steel, which reduces rotational mass and centrifugal force, making them ideal for high-speed applications.

- Corrosion resistance: Ceramic materials are less susceptible to corrosion, making them suitable for use in harsh environments or with corrosive materials.

- High Temperature Resistance: Ceramic materials can withstand higher temperatures than steel, so hybrid bearings are suitable for high temperature applications.

- Oil-free self-lubricating non-magnetic insulators.

- Rolling ball: using high-precision ceramic ball, small jump, high smoothness cage.

- No friction and no jamming clearance: the use of CO standard clearance, different increase clearance for smoothness.

- Tolerance: Inner diameter, outer diameter, height tolerance consistency (0.003MM)

Step 2

Application Field

- Automotive: Automotive turbo chargers have the highest speed requirements for bearings, requiring them to have good acceleration response, and low torque, low vibration and low temperature rise at high speeds.

- Electric motors: ceramic bearings can realize the permanent insulation of electric motors in deceleration and energy-saving tube loading applications, leakage caused by arc discharge.

- Spacecraft engines: ceramic bearings are used in spacecraft engine fuel pumps to ensure that they work for long periods of time in liquid nitrogen, liquid hydrogen and other media;

- Aircraft parts: ball screws equipped with ceramic balls can be used in aircraft flap adjusters; hybrid ceramic bearings can be used in the engine of gas turbines, the

- medical and surgical instruments: ceramic bearings have been used in high-speed dental drills and surgical saws. They are durable and can withstand sterilization.

- Food processing equipment and chemical instruments: ceramic bearings do not require high lubrication, can run without lubrication, and corrosion resistance is also very good;

- Superconducting devices: ceramic bearings are manufactured from non-magnetic materials, and can be used in superconducting devices and semiconductor manufacturing equipment to avoid electromagnetic interference.