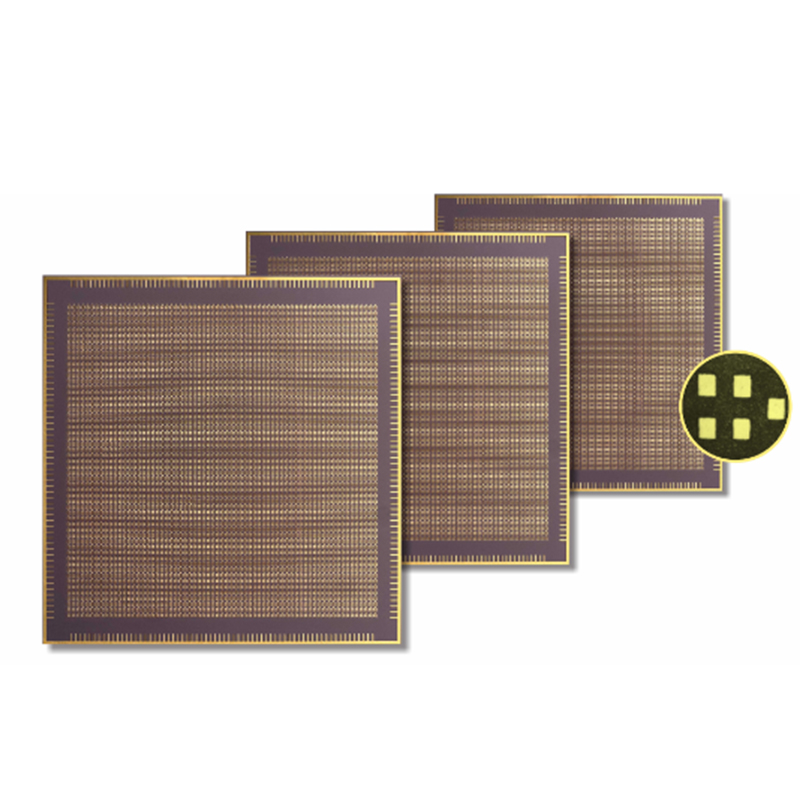

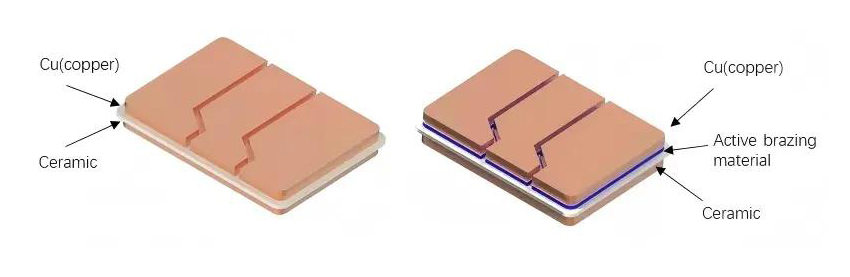

Direct Bonded Copper Substrates

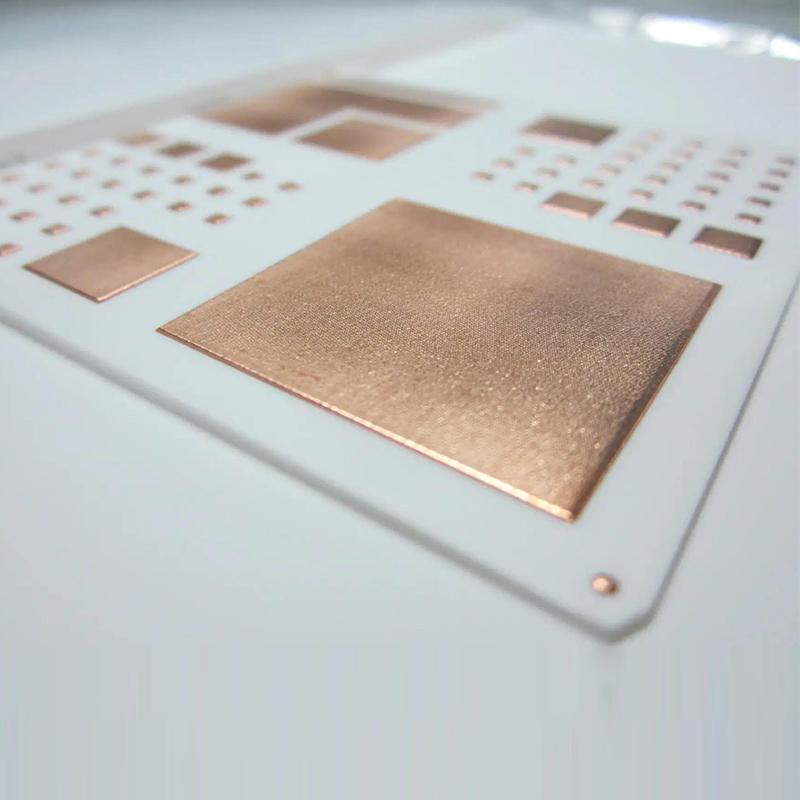

Copper-coated ceramic substrate is through a special process in the ceramic substrate single / double surface combined with copper substrate, in the power semiconductor products in a wide range of applications, the importance of the chip is second only to the chip, is the high power and high heat dissipation of the product is one of the core packaging materials.

Step 1

Product Features

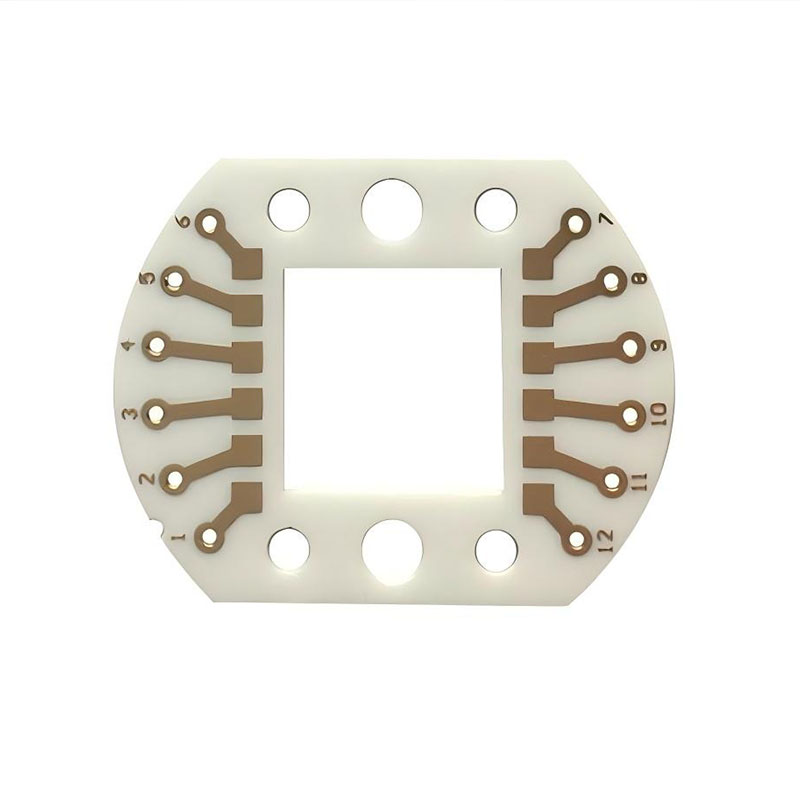

- Conductive interconnection

- Surface metallized copper-clad ceramic substrates have good solderability and conductivity, and can provide effective load-bearing and electrical connection for power chips, especially suitable for high-current applications.

- Electrical insulation

- The ceramic layer of the copper-clad ceramic substrate has good insulation properties, and its insulation voltage is usually >20kv/mm, which can effectively isolate the chip from external heat sinks.

- Heat dissipation channel

- Copper-clad ceramic substrate has good thermal conductivity, the thermal conductivity of the ceramic layer is usually 20-260W/mK, and the thermal conductivity of the copper layer is usually 386-401W/mK. In the traditional power module, more than 80% of the heat of the power chip is conducted to the outside of the power module through the copper-clad ceramic substrate.

- Mechanical support

- In addition to the above performance, copper-clad ceramic substrate has the function of carrying and supporting. Its high strength, not easy to deformation, coefficient of expansion and silicon close to a wide range of applicable temperatures, the above excellent mechanical properties to ensure the reliability of the product.

DBC ceramic substrate, short for Direct Bonded Copper Ceramic Substrate, is an advanced material composed of a ceramic substrate (typically Al2O3 or AlN) and copper, tightly joined together through a hypo-eutectic process. This unique combination of materials results in a substrate with exceptional thermal conductivity, low thermal expansion, high strength, and excellent wettability for soldering applications.

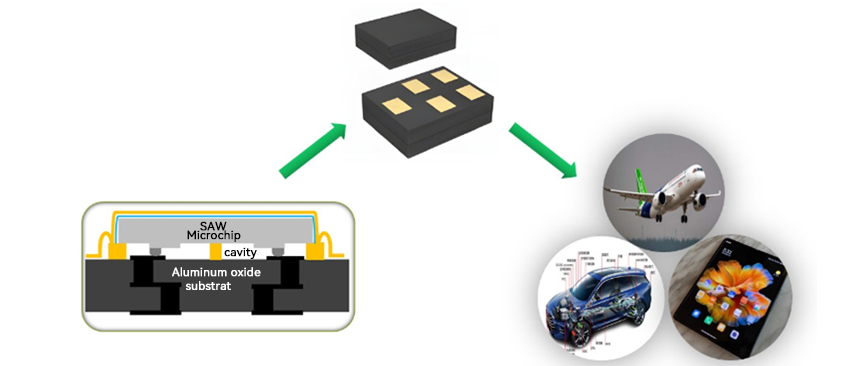

Step 2

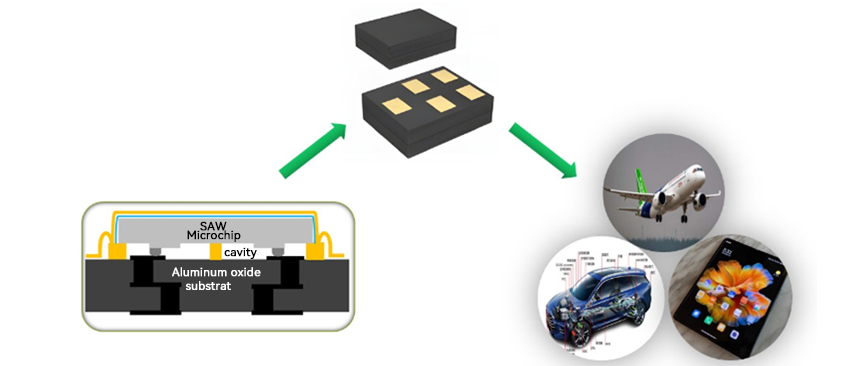

Application Field

– Power Electronics: IGBT, MOSFET, Thyristor Module, Solid-state Relay, Diode, Power Transistors

– Automotive: ABS, Power Steering, DC/DC Converter, LED Lighting, Ignition Control

– Home Appliance: Air Conditioner, Peltier Cooler

– Environmental Technology: Local Power Generation, Electric Vehicle, Traction Control System, Photovoltaic Units, Wind Power

– Industrial: LED Displays, Welding Machine

– Aerospace: Laser, Power Supply for Satellites and Aircrafts

– PC/IT: Power Supply, UPS System

– Automotive: ABS, Power Steering, DC/DC Converter, LED Lighting, Ignition Control

– Home Appliance: Air Conditioner, Peltier Cooler

– Environmental Technology: Local Power Generation, Electric Vehicle, Traction Control System, Photovoltaic Units, Wind Power

– Industrial: LED Displays, Welding Machine

– Aerospace: Laser, Power Supply for Satellites and Aircrafts

– PC/IT: Power Supply, UPS System