OURService

Advanced ceramic bring new value to the world

The R&D center has gathered professional talents in the domestic ceramic field from powder making to post-treatment, and possesses a high level of scientific research and technical capabilities. The R&D team is composed of the R&D department, the design conversion department, and the project department, with a total workforce of over 100 people. It possesses flexible and pragmatic design concepts, safeguarding the company’s core competitiveness and the technological content of its products.

laboratory

Have a professional R & D team

service

Friendly cooperation with customers

R&D Capabilities

- There Are Over 4,000 Product Categories, And The Annual R&D Investment Reaches About 10% Of The Company’s Total Revenue.

- Shenzhen University Laboratory We Have One-Stop Comprehensive Material And Application Solutions In The Fields Of Special Engineering Plastics And Special Ceramics

- The Proportion Of High-Level Software And Hardware R&D Talents And Mid-To-Senior Engineers In The Team Accounts For 60%, And R&D Laboratory Technicians And R&D Technicians Account For 30%. Four Complete And Well-Developed Reliability Laboratories Have Been Established.

- Perfect Product Data Management, Product Life Cycle Management, And Integrated Product Development System;

- With Over 10 Years Of Senior Experience In The Application Design Of Engineering Plastics And Rubber Special Materials;

- It Is Capable Of Providing A Complete Set Of Solutions Including Liquid Path Systems, Automatic Extraction And Pipetting Module Systems, Etc.

- We Have Obtained Over 100 Patents And Software Copyrights, And Possess Complete Independent Intellectual Property Rights.

- Together With Strategic Clients And Research Institutions, We Have Jointly Undertaken A Number Of National And Municipal Scientific And Technological Research Projects.

4000+

There are 4,000 product categories

4 place

A complete and reliable laboratory

10 years

Senior R&D experience

100+

Patents and software Copyrights

Technicalability

Core technology platform

With 15 years of in-depth research on advanced ceramic materials and application technologies, we have established four core technology platforms

Ceramic material development platform

Research and development and modification of ceramic materials

Product application design platform

Product application design based on ceramic materials

Ultra-precision processing platform

Ultra-precision processing of micron-sized brittle and hard materials

Simulation computing platform

Conduct targeted theoretical pre-research and analysis

Material research anddevelopment capability

The field of materials research

Porous ceramic material

Anti-Static Ceramic Materials

Conductive Ceramic Material

Precision Silicon Carbide<br>Ceramic Materials

Processable Ceramic Materials

Processable Ceramic Materials

Ceramic Metallization<br>(Molybdenum-Manganese)

Ultra-Thin Transparent<br>Ceramic Material

Zirconia Ceramics And<br>Alumina Ceramics

Black Aluminium Oxide

High Thermal Conductivity Ceramic

Piezoelectric Ceramics

High Dielectric Ceramics

Black Aluminium Nitride

Boron Nitride

Tantalum Carbide

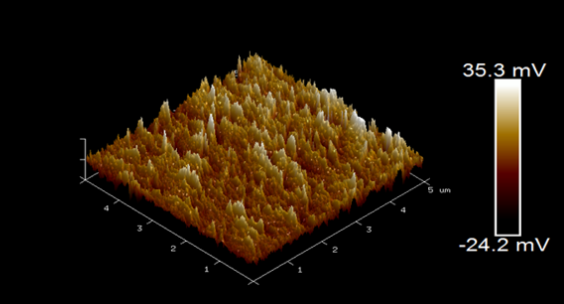

Detection of surface feature roughness

The most advanced characterization equipment is used to precisely detect the surface roughness of the product, down to the nanometer level.

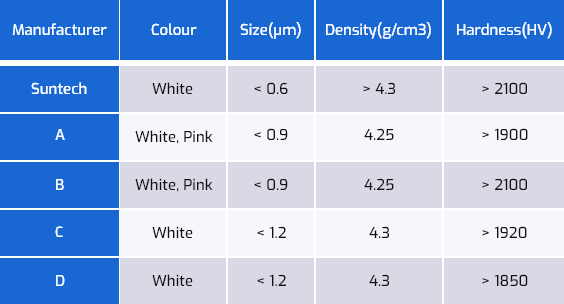

Comparison of material properties among various manufacturers

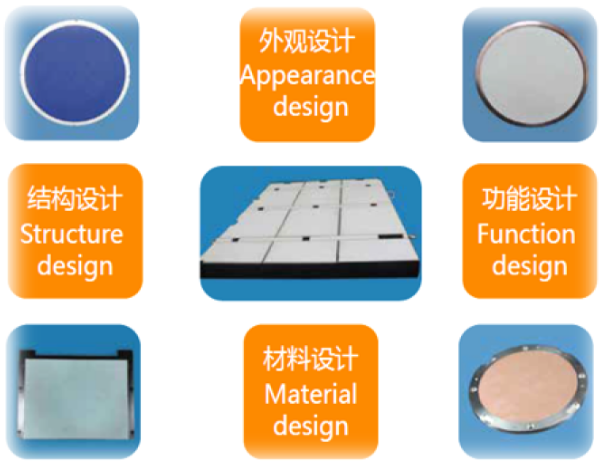

Design anddevelopment ability

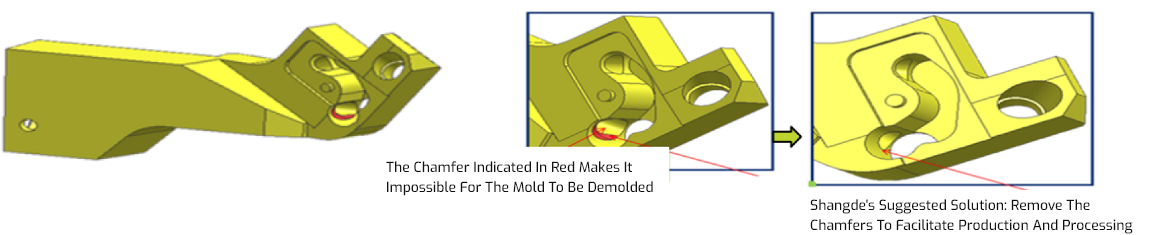

Design suggestion case

Sales Department Technical Support:

Provide Professional Ceramic Product Design Services For Customers

Engineering Technology:

Responsible For The Development Of New Products

Forming Technology:

Different Forming Processes Are Designed According To Different Demands

Machining Technology:

Responsible For The Mechanical Processing Technology Of Brittle And Hard Materials

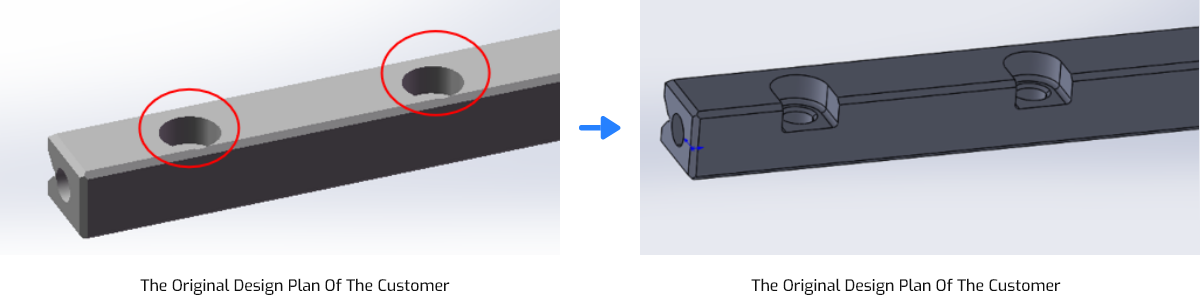

Customer 1

The world’s leading direct drive motor equipment factory

Based on the experience of ceramic machining, in order to facilitate processing and control costs, it is recommended that the customer change the design structure

Based on the experience of ceramic machining, in order to facilitate processing and control costs, it is recommended that the customer change the design structure

Customer 2

The World’s Leading Manufacturer Of Semiconductor Packaging equipment

Super-brittle andhard material

Ultra-precision processing capability

Ceramic flexible processing

For products with complex structures, setting programs for automatic processing can well control the processing accuracy and positional degree. The processing accuracy can reach 0.008MM, and the surface roughness can reach Ra0.4μm

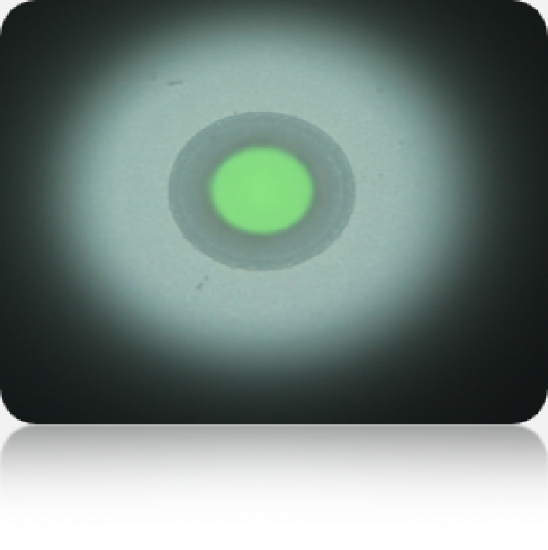

Ceramic micro-hole processing

For special products of ceramic with ultra-high precision and tiny holes, automatic processing of small holes is carried out to precisely control the size and roundness. The processing diameter ranges from 0.021 to 0.06mm, with a diameter accuracy of 0.002mm, a concentricity of 0.005mm, and a surface roughness of up to 0.2μm

The surface of the alloy is precisely mirror-polished

Precision polishing of small-sized alloy planes can achieve a surface roughness of Ra0.02um and a flatness of 0.005MM

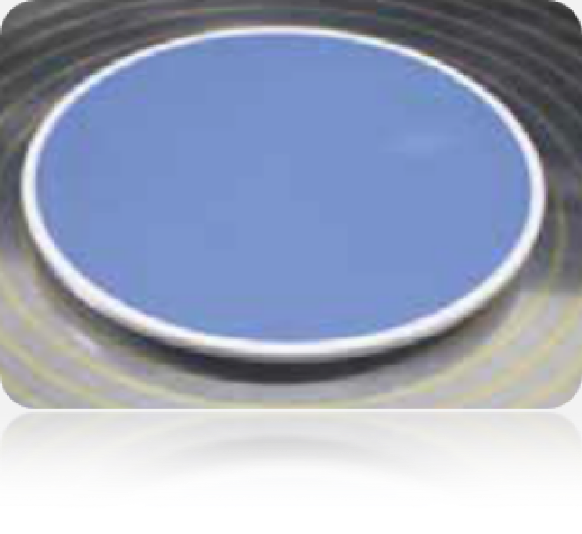

Process high-precision planes

The Processing Flatness Of A 4-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of A 6-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of An 8-Inch Diameter Can Reach 0.005MM.

The Flatness Of A 12-Inch Diameter Processing Can Reach 0.005 To 0.010MM

The Processing Flatness Of A 6-Inch Diameter Can Reach 0.003MM.

The Processing Flatness Of An 8-Inch Diameter Can Reach 0.005MM.

The Flatness Of A 12-Inch Diameter Processing Can Reach 0.005 To 0.010MM

OURService

Research and development strength

- 1. Product personalized customization and development strategy serving customers: The company’s product development strategy is based on the characteristics of the industry and serves the personalized needs of customers.

- 2. The product development model of IPD oriented towards customer demands The company implements the IPD product development model, guided by customer demands. Throughout the entire product development process, it adopts asynchronous and parallel methods, significantly shortening the product development cycle. The implementation of DFMEA, VRK and technical review control has greatly reduced product risks and ensured the standardization of the development process.

- 3. One-stop service to meet personalized customization: Kentuo Company’s products have basically achieved full coverage of product types in the field of microfluidic control. Meanwhile, the complete set of solutions for microfluidic control in various application fields has also matured and can meet customer needs in one stop.

- 4. Ultra-fast sampling: After years of accumulation of industry technology, Kentuo Company now has multiple mature technology platforms. On this basis, it can quickly achieve personalized customized sample delivery for customers.

Technicalability

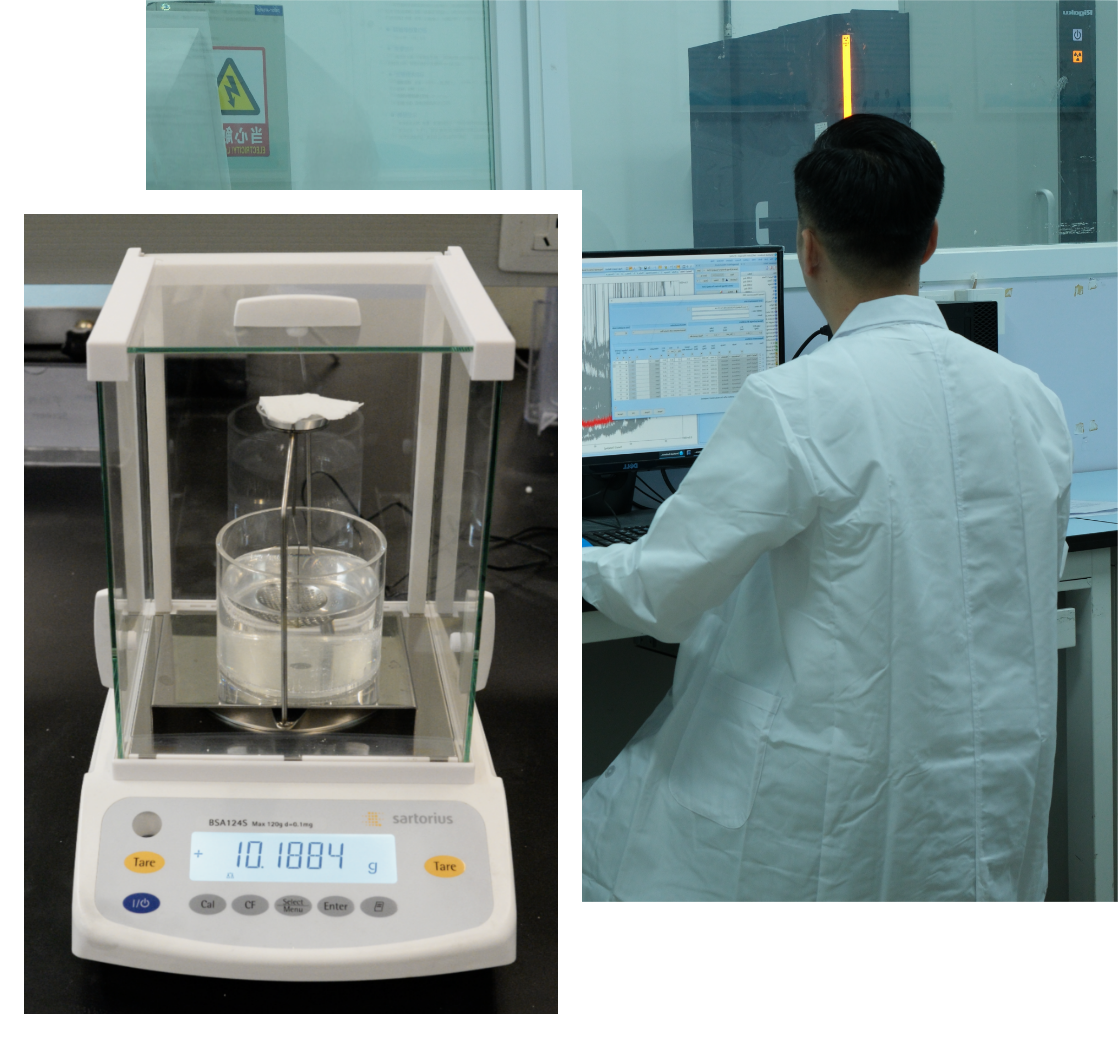

Laboratory equipment

High-temperature box furnace

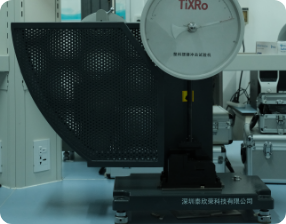

Pendulum impact testing machine

Discharge plasma sintering system

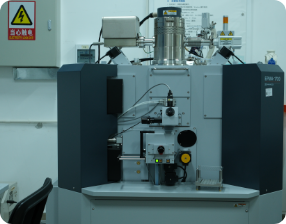

Electron probe microanalyzer

High-throughput and high-power discharge plasma sintering system

Electronic balance AUY120

High-temperature furnace

Electronic universal testing machine

Japanese Rikyo multi-functional X-ray diffractometer

Scanning electron microscope

Muffle furnace ksl-1700x

Density balance

Universal mechanical testing machine