Ceramic Materials Overview

Technical ceramic materials have the ability to make products lighter, more efficient, longer lasting, reduce maintenance intervals, and reduce operating costs. They are frequently being used to replace metals, polymers, and refractory materials in a wide variety of applications due to their notable high temperature capability, hardness, and electrical properties.

Loongceram offers a wide range of advanced technical ceramic materials to ensure that we have the right material for your application.

Loongceram offers a wide range of advanced technical ceramic materials to ensure that we have the right material for your application.

Zirconia Toughened Alumina

CeramAlox™

Zirconia Toughened Alumina (ZTA) is a high performance ceramic composite and a unique ceramic material by way of exhibiting a combination of high hardness, strength, wear and corrosion resistance.

Machinable Glass Ceramic

Ceramalum™

Machinable Glass Ceramic Is An Excellent Material To Use If High Thermal Conductivity And Electrical Insulation Properties Are Required — An Ideal Material For Use In Thermal Management And Electrical Applications.

Aluminum Nitride

CeramAlum™

Aluminum Nitride (AlN) is an excellent material to use if high thermal conductivity and electrical insulation properties are required — an ideal material for use in thermal management and electrical applications.

Alumina (Aluminium Oxide)

CeramAlox™

Alumina, also known as Aluminium Oxide, is a hard wearing advanced technical ceramic material frequently used in a wide variety of industrial applications.

Zirconia

CeramaZirc™

Unlike traditional ceramics that tend to be hard and brittle, Zirconia offers high strength, wear resistance, and flexibility far beyond those of most other technical ceramics.

Boron Nitride

Boron Nitride Grades

Boron Nitride (BN) is an advanced synthetic ceramic material available in solid and powder form. It has outstanding thermal conductivity, electrical insulation and thermal properties and is easy to machine.

Silicon Nitride

CeramaSil-N™

Silicon Nitride has the most versatile combination of mechanical, thermal, and electrical properties of any technical ceramic material.

Boron Carbide

DuraShock™ & DuraWear™

Boron Carbide (B4C), also known as black diamond, is the third hardest material after diamond and cubic boron nitride. It is a suitable material for many high performance applications due to its attractive combination of properties.

Silicon Carbide

CeramaSil-C™

Silicon Carbide (SiC) is one of the lightest, hardest, and strongest technical ceramic materials with exceptional thermal conductivity, acid resistance, and low thermal expansion.

Need help?

Not sure which ceramic material is right for your application? Learn more about Loongceram, check out our ceramic materials comparison chart, or contact us and we’ll be more than happy to help out.

Call Us For Service

+ 86-17319746990

Call 24/7 Anytime For Your Problem

Frequently Asked Questions

- What are technical ceramics?+Ceramics, defined by the broad definition of “inorganic solids”, are one of the main classes of materials, along with metals, polymers, and composites. There are several different types of ceramics, with technical ceramics (also known as engineered ceramics or advanced ceramics) being the group with the highest performing mechanical, electrical, and/or thermal properties. Their high performance is due in part to their extremely high purities which are most commonly metal compounds combined with oxides, carbides, or nitrides. Ceramics have the ability to increase product lifespan, increase efficiency, reduce overall maintenance costs, and improve performance.

- What are the advantages of technical ceramics?+High Hardness

One of the most common properties of engineered ceramics is extreme hardness (& stiffness) – some are more than 4 times harder than stainless steel. This high hardness directly translates into excellent wear resistance, meaning that many technical ceramics have the ability to keep their precise, high-tolerance finish much longer than any other material.

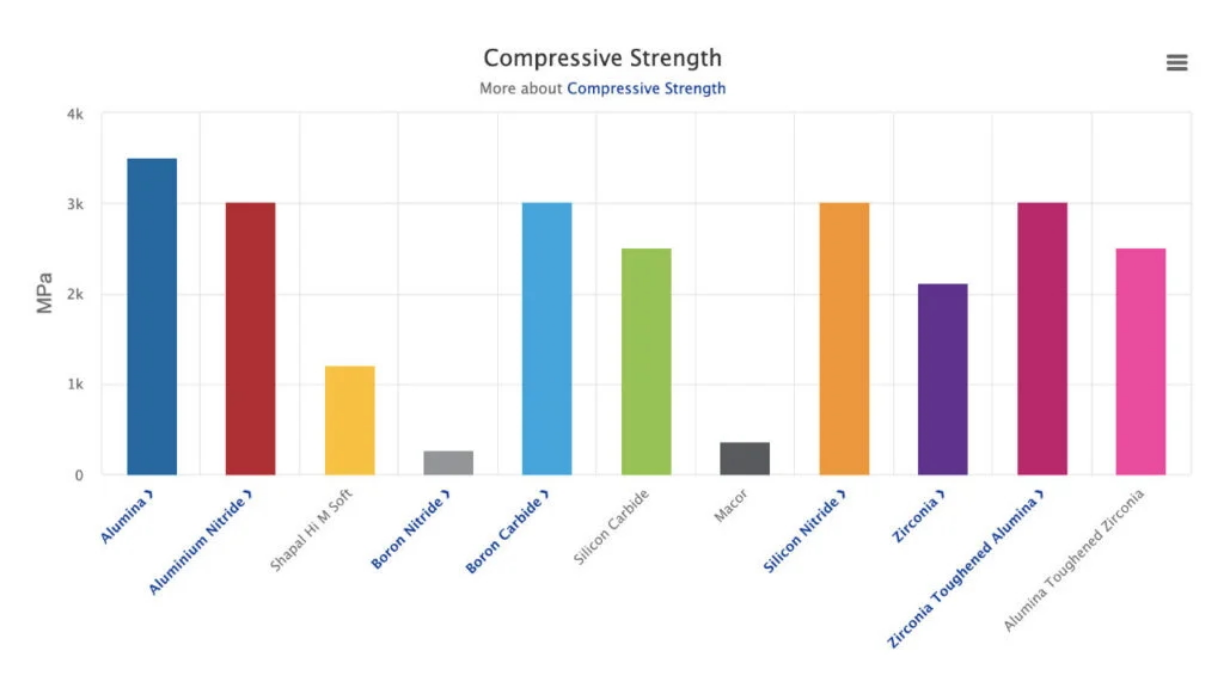

Extreme Compressive Strength

Technical ceramics have very high strength, however, this is only when compressed. For example, many technical ceramics can withstand extremely high loads ranging from 1000 to 4000 MPa. Titanium on the other hand, which is regarded as a very strong metal, only has 1000 MPa of compressional strength.

Low Density

Another common property of technical ceramics is their low density, ranging from 2 to 6 g/cc. This is significantly lighter than stainless steel (8 g/cc) and titanium (4.5 g/cc) with only the much softer aluminum being similar in density. Due to their high hardness and low weight, technical ceramics are increasingly being used in a variety of industries in applications where no other material can match their performance & long life.

Excellent Wear Resistance

Many technical ceramics are able to withstand incredibly high temperatures while still retaining their mechanical & electrical properties. Where all metals and polymers will start to compromise their properties, technical ceramics will continue to function with consistent performance and reliability. This property makes ceramics appropriate for use in very high temperature applications like furnaces, jet engines, brake systems, and cutting tools.

Excellent Electrical Properties

Technical ceramics tend to be excellent electric insulators (high dielectric strength). They are especially useful in high-temperature applications where other materials’ mechanical & thermal properties tend to degrade. Some ceramics have low electrical loss & high dielectric permittivity; these are typically used in electronic applications