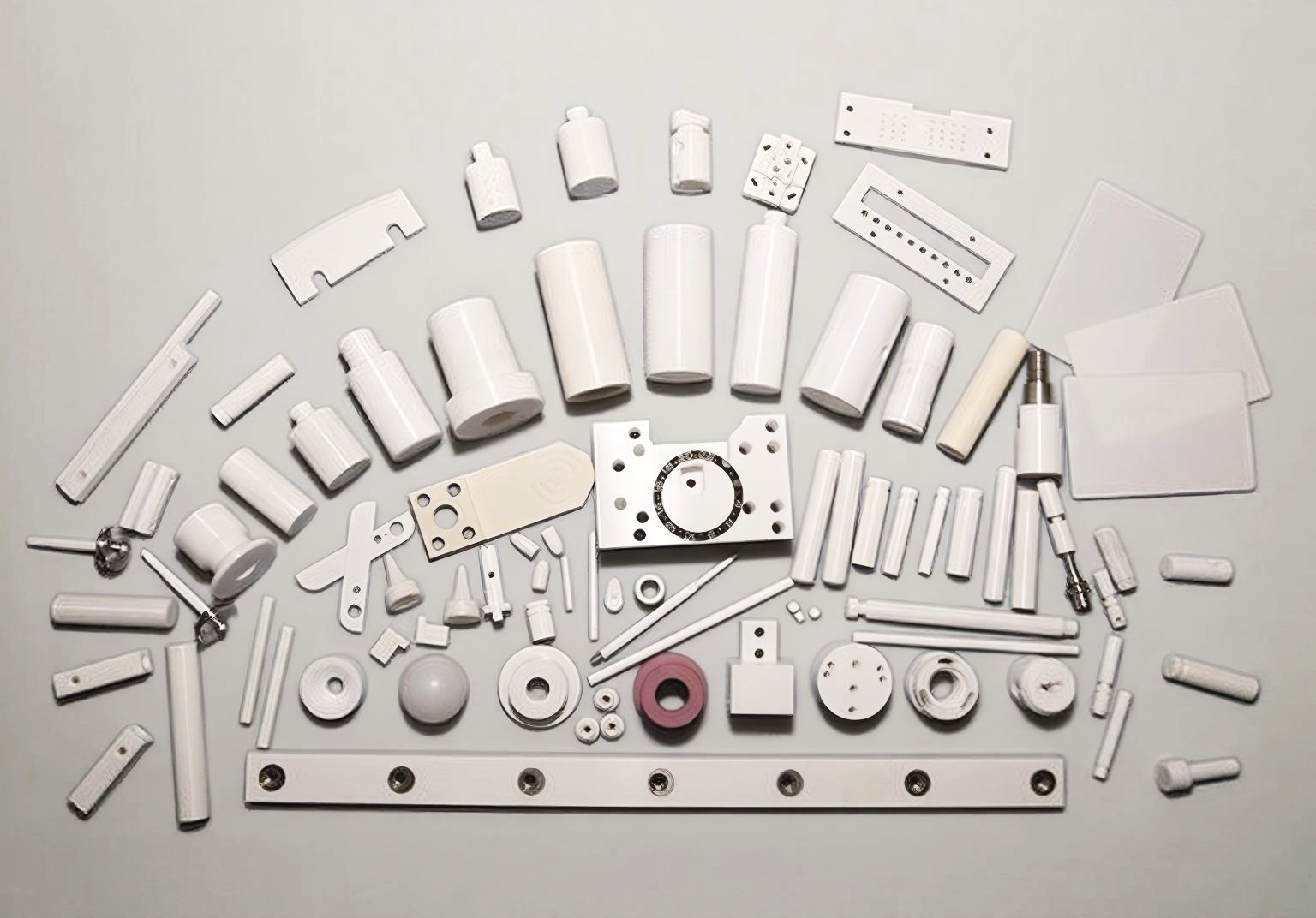

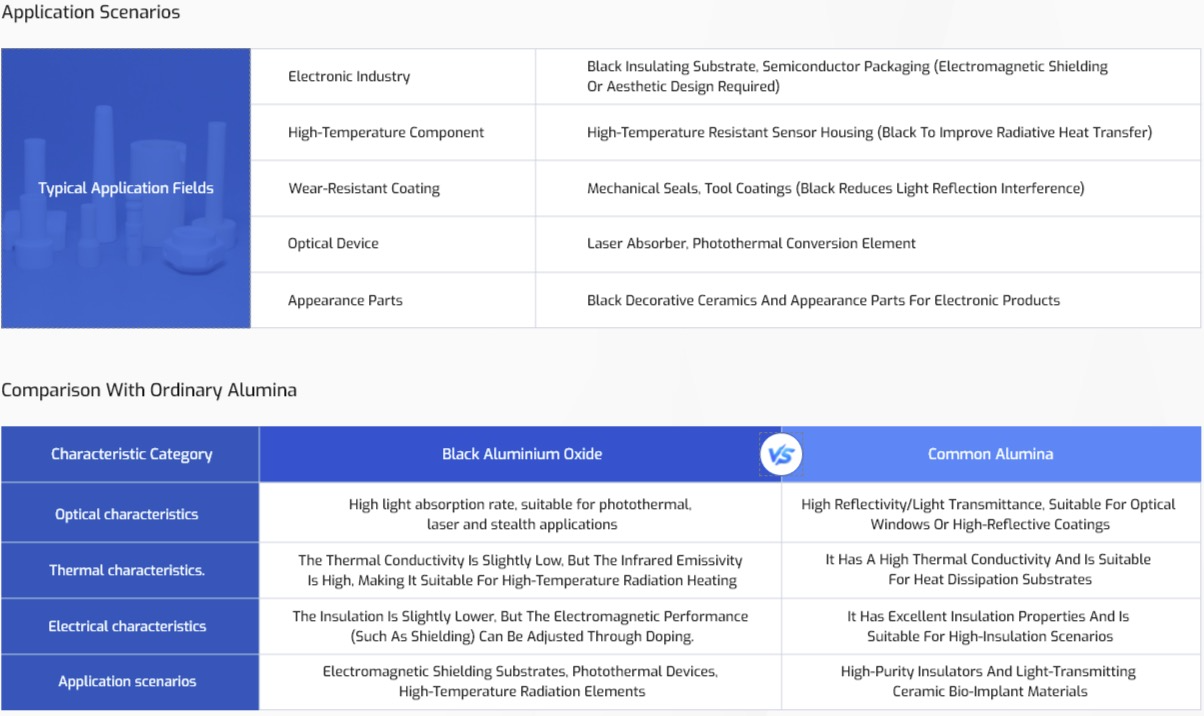

Black Alumina Ceramics, Like Traditional Alumina Ceramics, Possess Outstanding Properties Such As Excellent Insulation Performance, Small Expansion Coefficient, High Thermal Conductivity, High Mechanical Strength, Good Light-Blocking Property, Wear Resistance, And Low Dielectric Loss. Due To Their High Photosensitivity And Strong Light-Blocking Property, They Are Widely Used In The Fields Of Semiconductor Integrated Circuits And Electronic Product Packaging

Advantage

-Non-Reflective

-Easy To Recognize

-Good Heat Absorption Effect

-It Has Strong Light-Blocking Performance And Improves Electrical Insulation

-Better Thermal Conductivity And Enhanced Mechanical Strength

-Higher Chemical Durability And Excellent Dimensional Stability

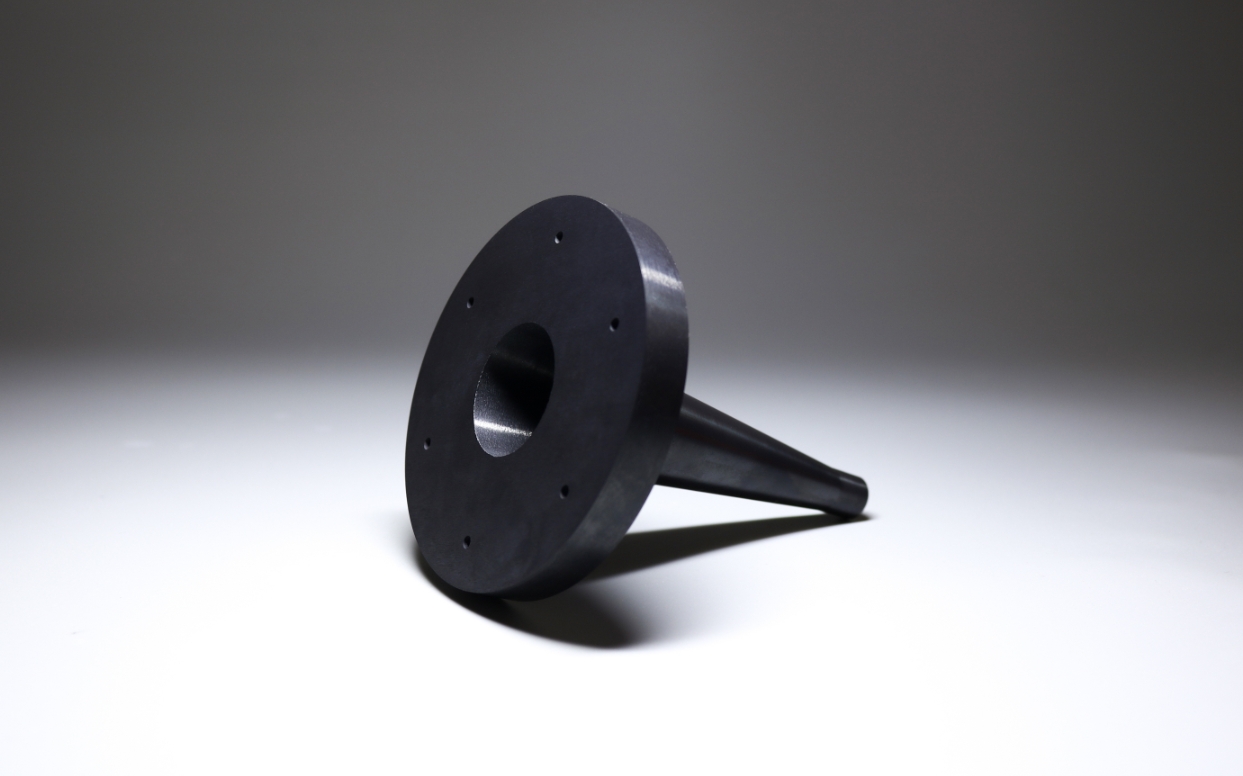

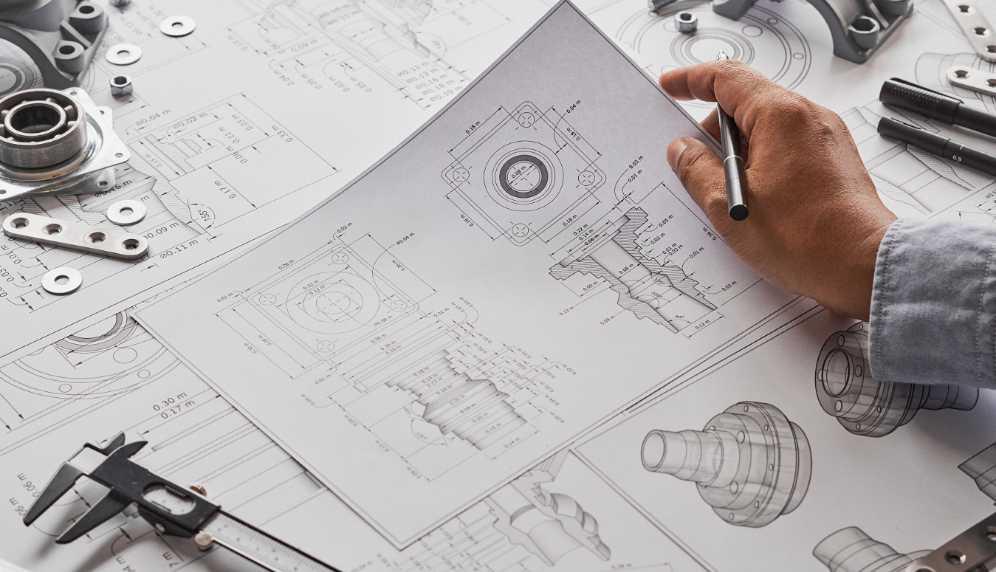

We will ask you about your interest in technical ceramics to solve the current problem. Just tell us what functions you want the ceramics to have, such as insulation, heat resistance, wear resistance, chemical resistance, rigidity, etc. In addition, please provide the drawings containing shape and size information.

Insulation, heat resistance

Wear resistance, chemical resistance, rigidity