Ceramic robot arm

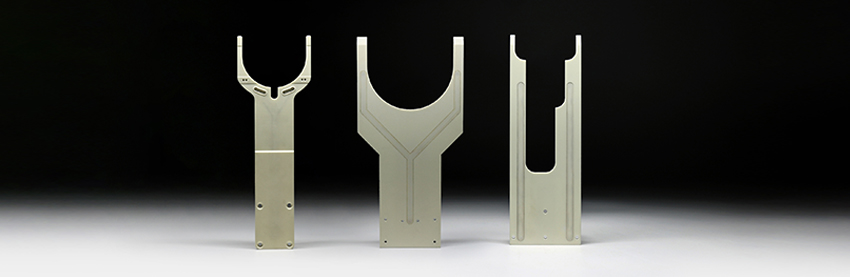

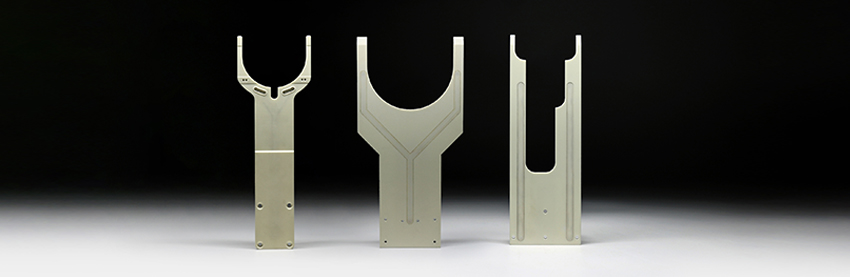

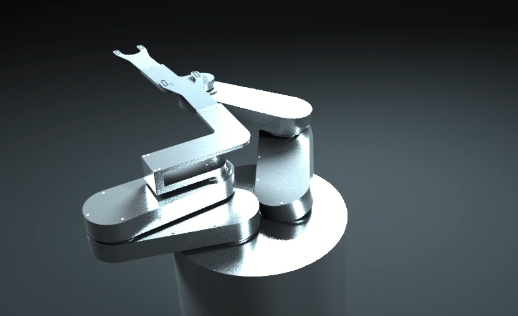

We offer precision ceramic arms made of different materials such as alumina, silicon carbide, etc., which are used in key aspects of electronic engineering for precise manipulation and handling. Precision ceramic arm is a handling arm with high hardness and abrasion resistant physical properties. At the same time in the high temperature environment still maintain good insulation and corrosion resistance and other physical properties. Precision equipment related to the field of electronic engineering is very demanding in terms of the performance of the components used, and the advanced precision ceramic material handling arm that we have produced and developed is able to meet these conditions. The surface coating is applied by a special process to enhance the durability and stability of the ceramic arms. We can customize them according to customer’s drawings or samples.

| Material Properties | Alumina (Al₂O₃) Ceramics | Silicon Carbide (SiC) Ceramics | Conductive Ceramics |

| Operating Temperature | Up to 1600°C | Up to 2200°C | – |

| Density | 3.9 g/cm³ | 3.1 g/cm³ | – |

| Hardness | 9 Mohs hardness | 9.5 Mohs hardness | – |

| Thermal Conductivity | 30 W/mK | 120 – 170 W/mK | – |

| Resistivity | >10¹⁴ Ω·cm | – | Resistivity can be customized according to specific electrical requirements |

| Corrosion Resistance | Excellent resistance to acids, alkalis and corrosive gases | Excellent resistance to acids, alkalis and corrosive gases | Excellent resistance to acids, alkalis and corrosive gases |

Step 1

Product Features

Enhanced Durability

Superior abrasion and corrosion resistance ensures that ceramic robotic arms last longer than traditional metal arms, reducing downtime and maintenance costs.

Energy efficiency

The lightweight nature of ceramic material reduces the load on the robot system, making it more energy efficient and faster at high speeds.

High-precision performance

With precision-engineered components, ceramic robotic arms provide high accuracy and smooth motion, which is critical for advanced automation systems.

Operational Versatility

The combination of alumina, silicon carbide, and conductive ceramics enables solutions for specific industrial challenges, whether electrical insulation, conductivity, or high temperature resistance is required.

Superior abrasion and corrosion resistance ensures that ceramic robotic arms last longer than traditional metal arms, reducing downtime and maintenance costs.

Energy efficiency

The lightweight nature of ceramic material reduces the load on the robot system, making it more energy efficient and faster at high speeds.

High-precision performance

With precision-engineered components, ceramic robotic arms provide high accuracy and smooth motion, which is critical for advanced automation systems.

Operational Versatility

The combination of alumina, silicon carbide, and conductive ceramics enables solutions for specific industrial challenges, whether electrical insulation, conductivity, or high temperature resistance is required.

Step 2

Application Field

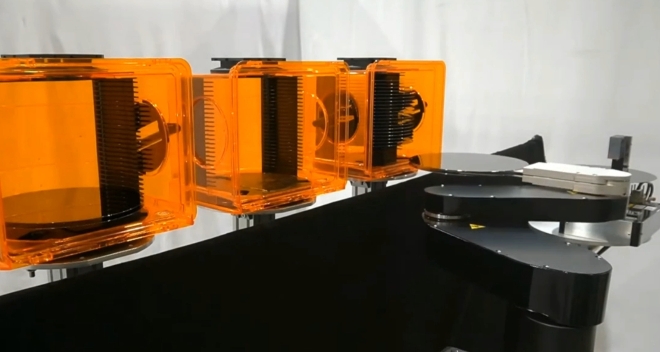

Semiconductor Manufacturing

Is ideally suited to perform wafer handling and high-precision movement in environments where metal contamination must be avoided.

Chemical Processing

Ideal for robotic operations in aggressive chemical environments where conventional materials degrade over time. Silicon Carbide and Aluminium Oxide offer excellent resistance to acids and alkalis

High Temperature Manufacturing

Used in industries such as glass production, foundry and metallurgy, which require materials that maintain strength and stability at extreme temperatures.

Electrical and Electronics Industry

Conductive Ceramic Robotic Arms are ideal for handling electronic components in static-sensitive environments, providing durability and conductivity when needed.

Automotive & Aerospace

These robotic arms are used in precision manufacturing processes where strength, lightweight materials, and abrasion and chemical resistance are critical for high-performance operations.