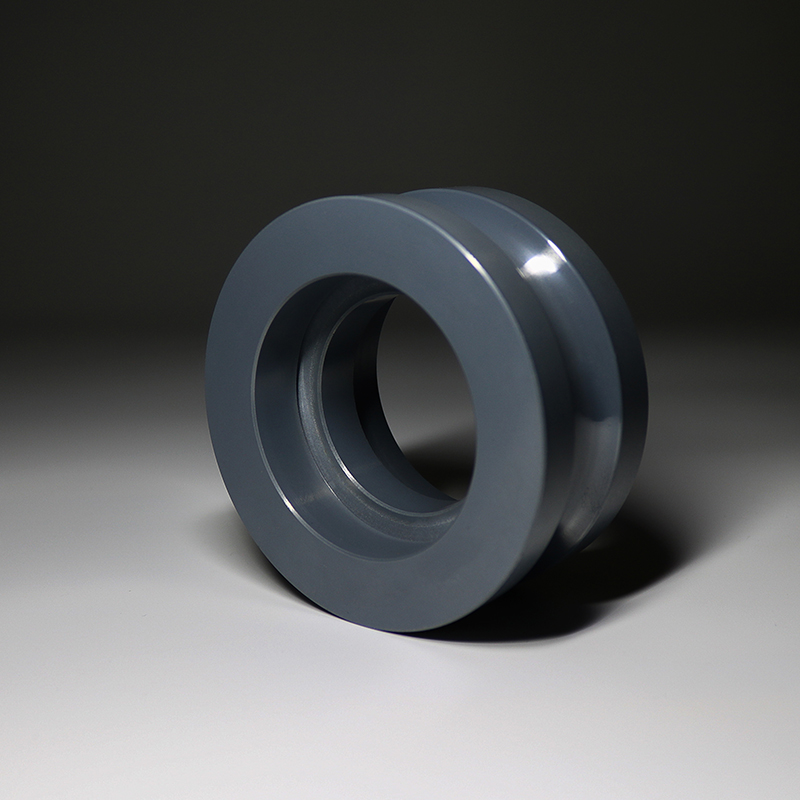

Silicon Nitride Welding Roller

Welding rolls apply pressure to the tube while heating the metal (usually by high-frequency induction heating), a combination that produces a forged weld.

The process places a number of demands on the weld roll material. It needs to have high strength, thermal shock resistance, wear resistance and high electrical resistance. In addition, the pipe temperature can be close to the melting point of the metal, so a high degree of temperature stability is required.

The process places a number of demands on the weld roll material. It needs to have high strength, thermal shock resistance, wear resistance and high electrical resistance. In addition, the pipe temperature can be close to the melting point of the metal, so a high degree of temperature stability is required.

Silicon nitride ceramics – the ideal material for welding processes

Loongeram has developed a silicon nitride material specifically for the high demands of this joining method, which ensures a long service life and improved precision while reducing wear. In addition to high bending strength and hardness, the gas pressure-sintered ceramic material excels by virtue of its high compressive strength and resistance to thermal shock. Another advantage is the electrical insulation provided by this silicon nitride ceramic.

‘Silicon nitride is unequivocally a more suitable ceramic material for the comprehensive performance of welding processes than other ceramic materials.’

SEM images show non-sparsely arranged, hexagonal, needle-shaped silicon nitride crystals. These crystals are interlocked to form an extremely tough material. The homogeneously distributed glass fibres, shown as white areas in the image, produce excellent high-temperature properties.

Gas Pressure Sintered Silicon Nitride Ceramics – Comparison of Ceramic Materials:

Loongeram has developed a silicon nitride material specifically for the high demands of this joining method, which ensures a long service life and improved precision while reducing wear. In addition to high bending strength and hardness, the gas pressure-sintered ceramic material excels by virtue of its high compressive strength and resistance to thermal shock. Another advantage is the electrical insulation provided by this silicon nitride ceramic.

‘Silicon nitride is unequivocally a more suitable ceramic material for the comprehensive performance of welding processes than other ceramic materials.’

SEM images show non-sparsely arranged, hexagonal, needle-shaped silicon nitride crystals. These crystals are interlocked to form an extremely tough material. The homogeneously distributed glass fibres, shown as white areas in the image, produce excellent high-temperature properties.

Gas Pressure Sintered Silicon Nitride Ceramics – Comparison of Ceramic Materials:

| Material Properties | Unit | Silicon Nitride Z-200 | Zirconia Z-300 | Alumina A-300 |

| Processing Method | – | Gas Pressure Sintering | Yttria-Stabilized | 99.70% |

| Density | g/cm³ | 3.2 | 6.05 | 3.9 |

| Compressive Strength | MPa | 3000 | 2300 | 2450 |

| Bending Strength | MPa | 850 | 1100 | 600 |

| Rockwell Hardness | HRA | 92 | 90 | 90 |

| Fracture Toughness | MPa·m1/2 | 7 | 7.5 | 5 |

| Thermal Conductivity | W/m·K | 30 | 3 | 32 |

| Maximum Operating Temperature | °C | 1400 | 1000 | 1000 |

Step 1

Product Features

High Temperature Resistance

Ceramic rollers can withstand the extreme temperatures often encountered in the welding process, making them more durable and reliable than metal rollers.

Wear Resistance

Due to their hardness and material properties, ceramic welding rollers are resistant to wear and deformation, ensuring consistent performance over time.

Improved weld quality

These rollers provide consistent, uniform pressure during the welding process, which helps to improve weld quality and reduce defects.

Reduced Maintenance

The durability of the ceramic material means that these rollers do not require frequent replacement and maintenance, thus improving overall operational efficiency.

Versatility in welding applications

Ceramic welding rollers are used for a variety of welding methods in different industries, including MIG, TIG and resistance welding.

Ceramic rollers can withstand the extreme temperatures often encountered in the welding process, making them more durable and reliable than metal rollers.

Wear Resistance

Due to their hardness and material properties, ceramic welding rollers are resistant to wear and deformation, ensuring consistent performance over time.

Improved weld quality

These rollers provide consistent, uniform pressure during the welding process, which helps to improve weld quality and reduce defects.

Reduced Maintenance

The durability of the ceramic material means that these rollers do not require frequent replacement and maintenance, thus improving overall operational efficiency.

Versatility in welding applications

Ceramic welding rollers are used for a variety of welding methods in different industries, including MIG, TIG and resistance welding.

Step 2

Application Field

Automobile manufacturing

Spot/seam welding of car bodies: This is the area where silicon nitride welding rollers are most widely used and in demand. Resistance spot and seam welding is used extensively to join steel sheets together in the manufacture of car bodies.

New energy power battery manufacturing

Seal welding of battery shell (steel/aluminum shell): In the production of square or cylindrical power batteries (e.g. lithium batteries), the last process is usually to seal weld the top cover (cover plate) to the shell (often using laser welding or resistance welding).

Aerospace & Rail Transportation

Welding of critical structural components for aircraft/high-speed rail/subway: These industries have extremely stringent requirements for welding quality and reliability.

Spot/seam welding of car bodies: This is the area where silicon nitride welding rollers are most widely used and in demand. Resistance spot and seam welding is used extensively to join steel sheets together in the manufacture of car bodies.

New energy power battery manufacturing

Seal welding of battery shell (steel/aluminum shell): In the production of square or cylindrical power batteries (e.g. lithium batteries), the last process is usually to seal weld the top cover (cover plate) to the shell (often using laser welding or resistance welding).

Aerospace & Rail Transportation

Welding of critical structural components for aircraft/high-speed rail/subway: These industries have extremely stringent requirements for welding quality and reliability.