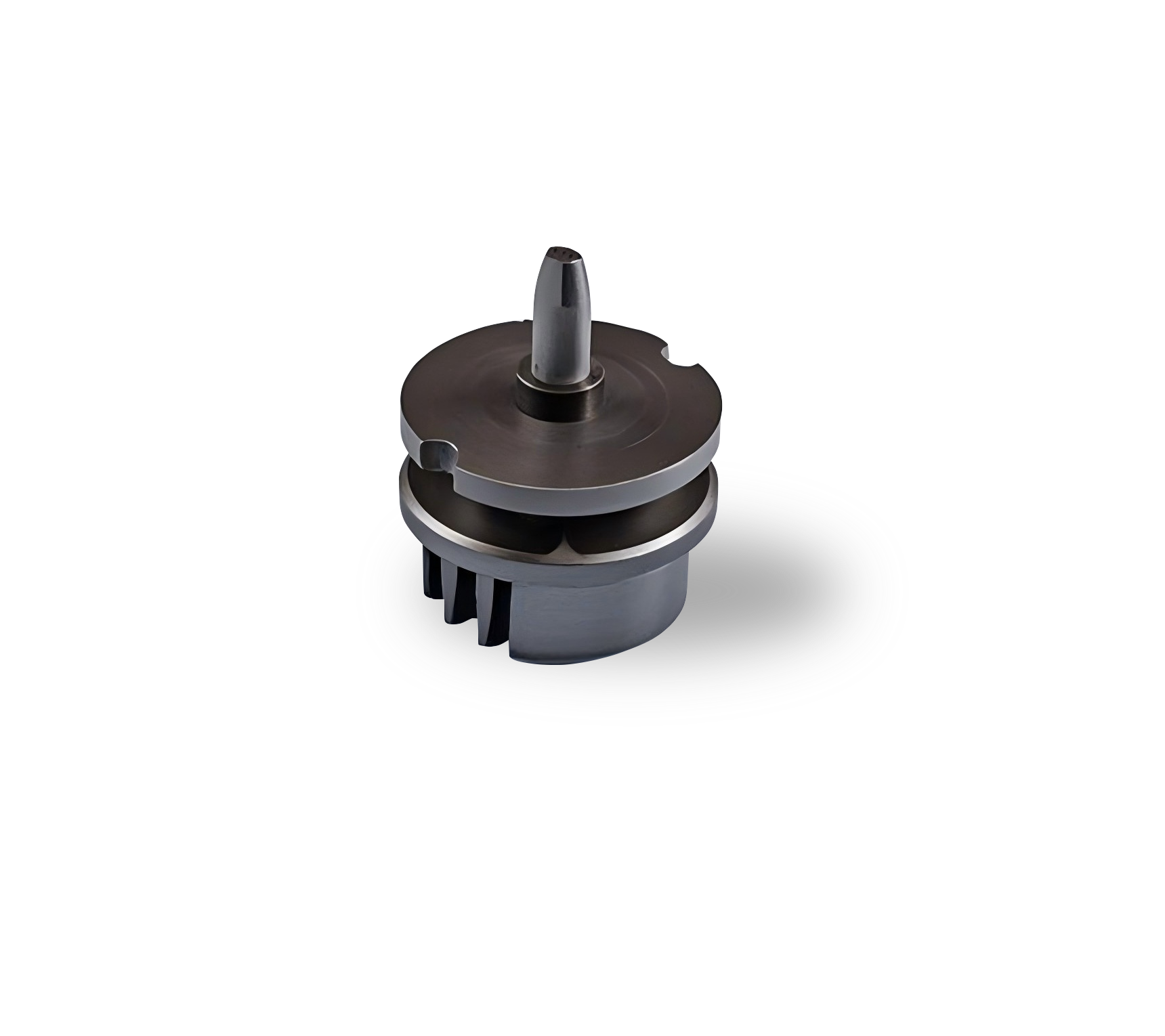

SMT Ceramic anti-static nozzles

Our ceramic anti-static nozzles are specialised tools designed to meet the needs of high-precision adsorption operations. With advanced ceramic materials and unique

technology, they are excellent in precision operations in electronics, semiconductors and many other fields, providing stable and reliable adsorption solutions for your production process.

technology, they are excellent in precision operations in electronics, semiconductors and many other fields, providing stable and reliable adsorption solutions for your production process.

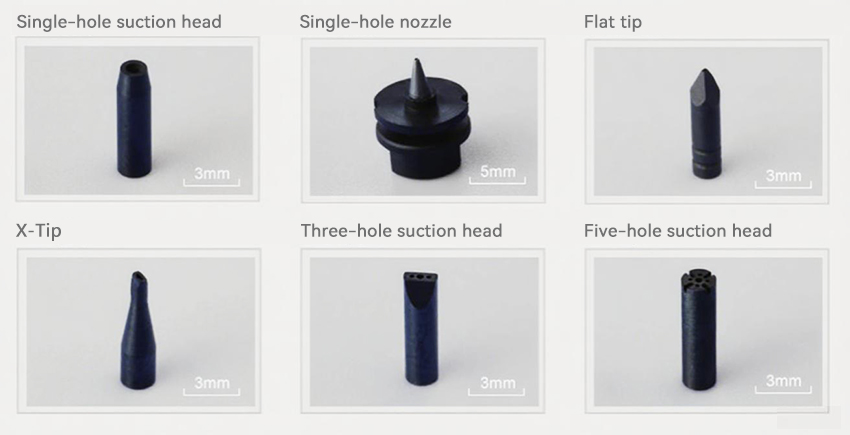

| Name | Material | Color | Application Characteristics | Machining Difficulty |

| Single Nozzle Tip | Zirconia | Black/Silver | wear resistant, ESD | requiring small hole diameter, high precision |

| Flat Nozzle Tip | ||||

| 3-hole Nozzle Tip | ||||

| 5-hole Nozzle Tip | ||||

| X Shape Nozzle Tip |

Step 1

Product Features

Excellent anti-static performance

is made of ceramic material with special formula and process, which has excellent anti-static ability. Its surface resistance is in the ideal range, which can effectively prevent static electricity from accumulating, avoiding dust, particles and other pollutants adsorbed due to static electricity, as well as the damage caused by electrostatic discharge to precision electronic components, ensuring the adsorption process to be safe and clean, especially suitable for static-sensitive chips, sensors, and other components of the handling and assembly.

High-precision manufacturing process

The shape and size precision of the suction nozzle reaches micron level. Both the aperture of the tip and the overall contour of the nozzle are manufactured in strict accordance with high-precision standards. This enables the nozzle to accurately adapt to various types of precision components, achieve stable and reliable adsorption and release operations, and effectively reduce the defective rate of products due to deviations in the adsorption position or uneven adsorption force.

Good abrasion and corrosion resistance

ceramic material gives the nozzle excellent abrasion resistance, in the frequent adsorption and release cycle operation, it can effectively resist the friction of the component surface, to maintain the long-term stability of the shape and size of the nozzle. At the same time, its excellent chemical stability, good resistance to a variety of chemical reagents, cleaning agents, etc., convenient for daily cleaning and maintenance, to extend the service life and reduce the overall cost of use.

Optimised adsorption structure design

The unique internal structure design makes the airflow distribution of the nozzle more uniform and reasonable. In the adsorption process, it can quickly generate stable adsorption force, firmly grasp the components; when releasing, it can quickly eliminate the adsorption force to ensure that the components are smoothly detached, which greatly improves the production efficiency and smoothness of operation.

is made of ceramic material with special formula and process, which has excellent anti-static ability. Its surface resistance is in the ideal range, which can effectively prevent static electricity from accumulating, avoiding dust, particles and other pollutants adsorbed due to static electricity, as well as the damage caused by electrostatic discharge to precision electronic components, ensuring the adsorption process to be safe and clean, especially suitable for static-sensitive chips, sensors, and other components of the handling and assembly.

High-precision manufacturing process

The shape and size precision of the suction nozzle reaches micron level. Both the aperture of the tip and the overall contour of the nozzle are manufactured in strict accordance with high-precision standards. This enables the nozzle to accurately adapt to various types of precision components, achieve stable and reliable adsorption and release operations, and effectively reduce the defective rate of products due to deviations in the adsorption position or uneven adsorption force.

Good abrasion and corrosion resistance

ceramic material gives the nozzle excellent abrasion resistance, in the frequent adsorption and release cycle operation, it can effectively resist the friction of the component surface, to maintain the long-term stability of the shape and size of the nozzle. At the same time, its excellent chemical stability, good resistance to a variety of chemical reagents, cleaning agents, etc., convenient for daily cleaning and maintenance, to extend the service life and reduce the overall cost of use.

Optimised adsorption structure design

The unique internal structure design makes the airflow distribution of the nozzle more uniform and reasonable. In the adsorption process, it can quickly generate stable adsorption force, firmly grasp the components; when releasing, it can quickly eliminate the adsorption force to ensure that the components are smoothly detached, which greatly improves the production efficiency and smoothness of operation.

Step 2

Application Field

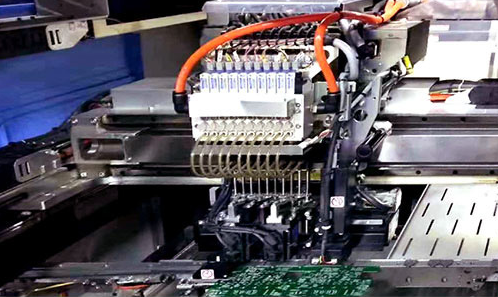

Electronic Manufacturing Industry

In the process of chip packaging, SMT mounting, semiconductor device assembly, etc., ceramic anti-static nozzles can accurately adsorb tiny chips, resistors, capacitors and other electronic components, avoiding static damage to the components, and safeguarding the performance and quality of electronic products.

Optical field

For the handling and installation of precision optical components such as optical lenses, lenses, etc., the high precision and anti-static characteristics of the suction nozzle can prevent the surface of the components from being contaminated with dust and static damage, and ensure that the optical performance of the optical components will not be affecte.

Microelectromechanical Systems (MEMS) Manufacturing

In the production process of MEMS devices, many tiny and precise structural parts need to be accurately adsorbed and handled. Ceramic anti-static nozzles are indispensable tools for MEMS manufacturing due to their high precision, anti-static and stable adsorption advantage