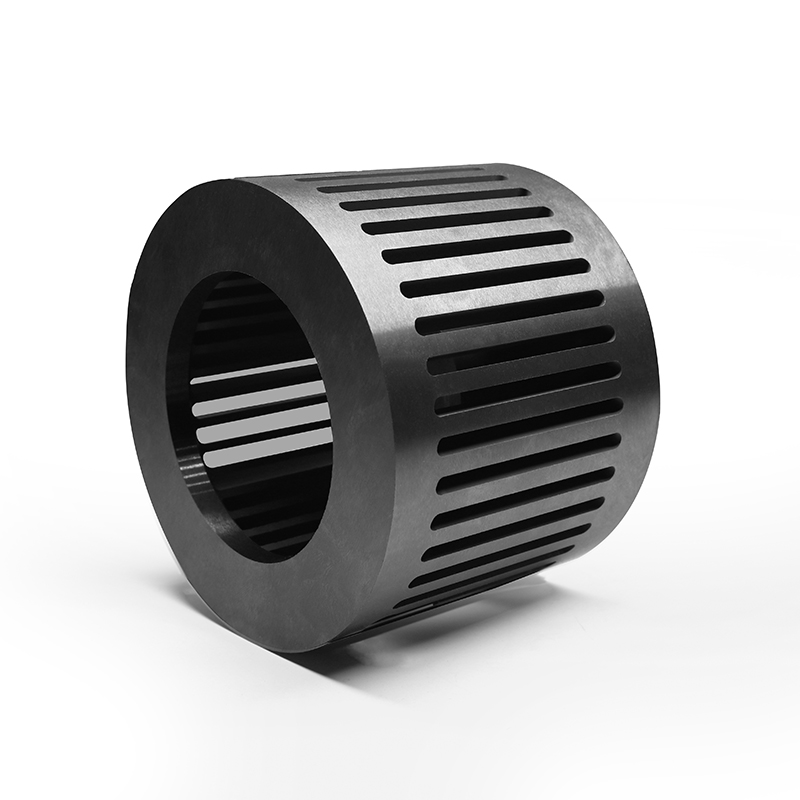

Silicon Nitride Grading Wheel

Ceramic classification wheel has excellent wear resistance, corrosion resistance, high purity and other characteristics of the manufacturing of key classification components, mainly used in airflow crushing / classification equipment. It accurately separates material particles by size through the centrifugal force field generated by high-speed rotation, which is the core guarantee for the production of high-quality, ultra-fine, metal pollution-free powders.

Step 1

Product Features

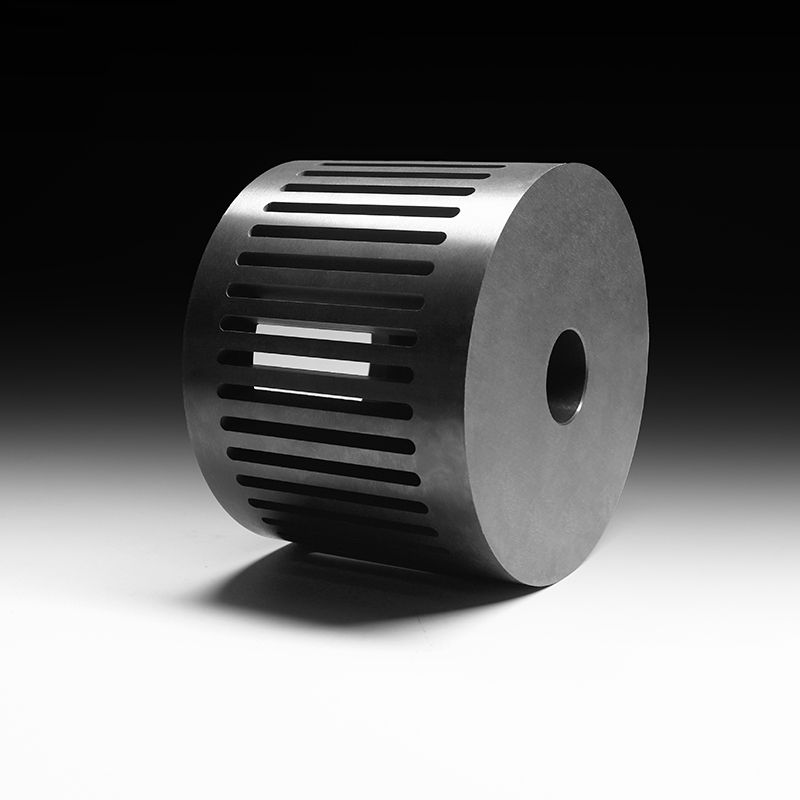

- Particle Classification: Inside the air flow pulverizer or classifier, a mixture of material particles of different sizes move with the air flow. The ceramic classifier wheel rotates at high speed, generating a strong centrifugal force.

- Separation of sizes: The particles are moved by a combination of centrifugal force and airflow traction:

- Coarse particles: the centrifugal force is greater than the trailing force of the airflow, and they are thrown to the outer edge of the classifier wheel and fall into the coarse powder collection area or return to the pulverizing area to continue pulverizing.

- Fine particles: the air flow traction force is greater than the centrifugal force, they are sucked into the inner part of the classifier wheel, and enter the fine powder collection system (e.g. cyclone separator, dust collector) with the air flow.

- Particle size control: By adjusting the rotational speed of the classifier wheel, the particle size of the final product (fines) can be precisely controlled. The higher the rotational speed, the greater the centrifugal force, only the finer particles can be carried away by the airflow, the finer the product size; on the contrary, the lower the rotational speed, the coarser the product size.

Step 2

Application Field

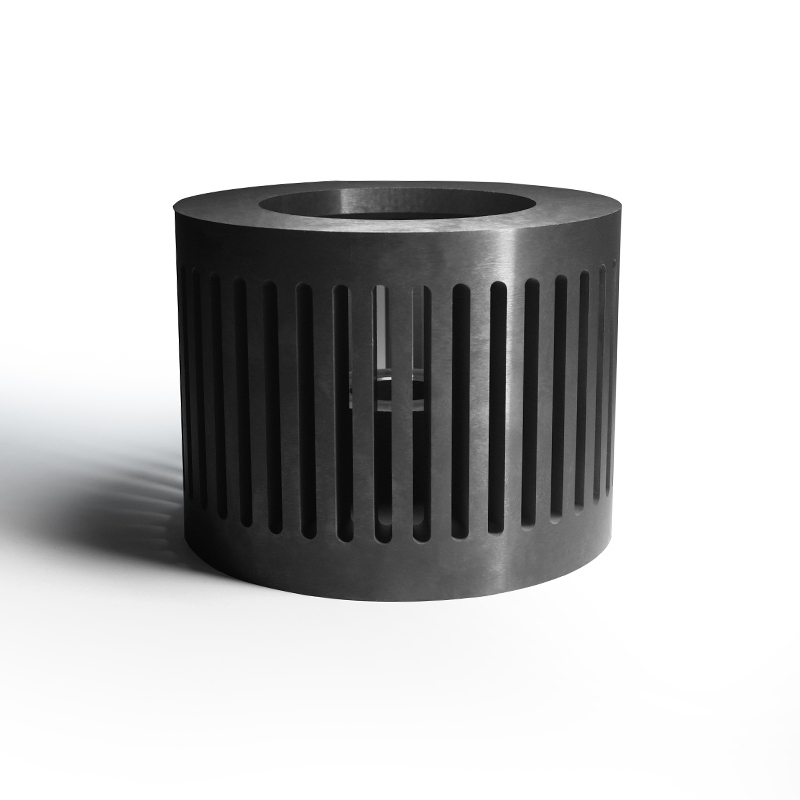

- Air flow pulverizing/classifying system: This is the most important application scenario of ceramic classifier wheel, which is used for the production of ultra-fine powders (micron and sub-micron).

- Non-metallic mineral powder processing: such as calcium carbonate, talcum powder, kaolin, quartz sand, mica, graphite and so on.

- Chemical industry: pigments, dyes, fillers, catalysts, flame retardants, pesticides and so on.

- New material industry: lithium battery positive and negative materials.

- Pharmaceutical and food industry: raw materials, auxiliary materials, additives, etc. that require high purity and no metal pollution.

- Electronic industry: electronic ceramic powder, phosphor.