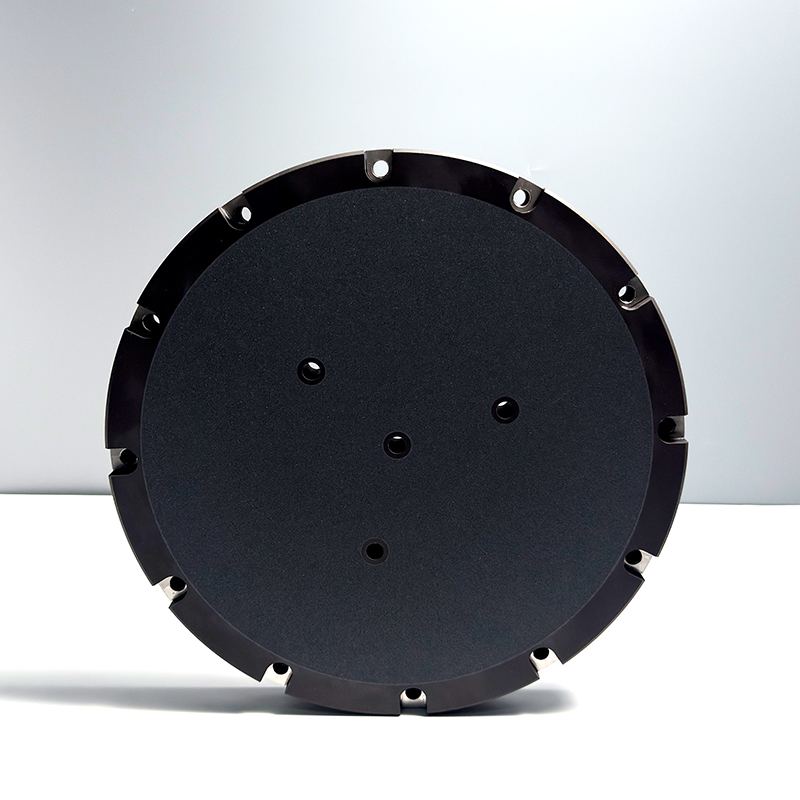

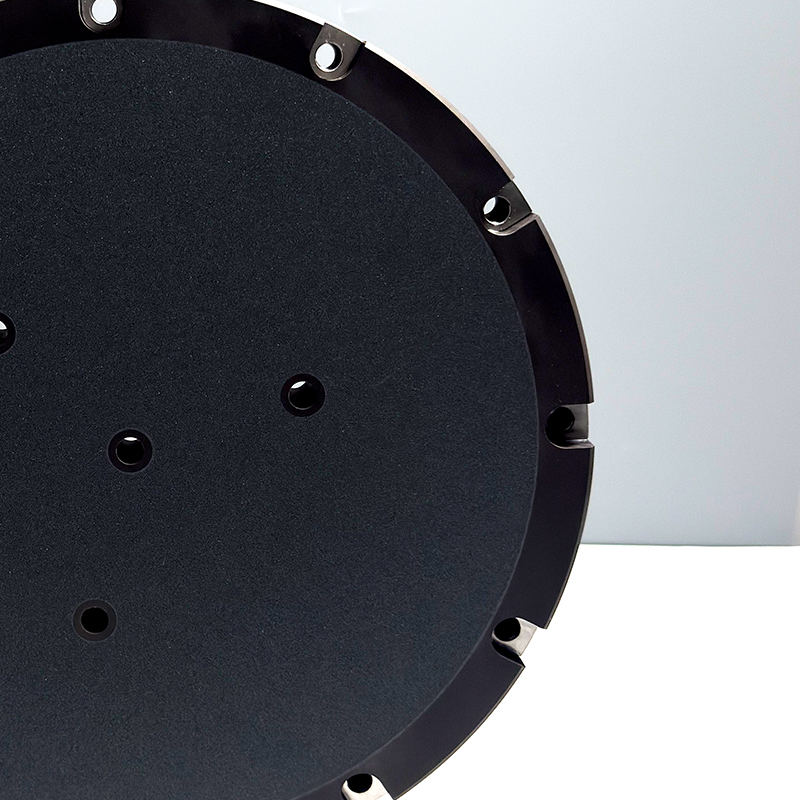

Porous Suction Cup

The process excels in precise operations in many fields such as electronics and semiconductors, providing stable and reliable adsorption solutions for your production processes.Ceramic vacuum suction cups have the characteristics of high flatness, high parallelism, dense and uniform organization, high hardness, good permeability, easy to trim and so on. Miniature aperture and uniform distribution, internal through each other, after grinding, the surface is smooth and delicate, good flatness, at the same time with super equipment stability and adsorption uniformity. These ceramic vacuum chuck products are important tools in the field of electronic engineering, widely used in picking up, handling, positioning and fixing various workpieces to ensure the safety and precision of the production process. Including alumina, silicon carbide, aluminum nitride and other precision ceramic materials suction cups, can be customized according to user requirements.

| Specification | Size | 4 inch | 6 inch | 8 inch | 12 inch |

| Flatness | 3μm | 3μm | 5μm | 5μm | |

| Porous ceramic color | White、green、yellow、black、blue、brown | ||||

| Porous ceramic material | Aluminium oxide,Silicon carbide | ||||

| Porous ceramic pore size | 20—-100μm | ||||

| Porous ceramic porosity | 30%—-45% | ||||

| Antistatic function | Optional | ||||

| Base material | Stainless steel, Aluminum alloy and Ceramics, Silicon Carbide | ||||

Step 1

Product Features

Ceramic vacuum chucks are widely used in the field of electronic engineering for processing and fixing of special products for thinning and cutting procedures.

- Flatness, high parallelism

- Dense and uniform tissue, high strength

- Good permeability, uniform adsorption

- Easy to dress

Step 2

Application Field

| Application | Field | Application |

| Printing | Screen printing、Paper industry、Paint inspection、Pixel detection | |

| Semiconductor | Bonding;Dicing;Tape mounter;Polishing | |

| Processing | Metal processing;Machining;Laser processing | |

| LED/LCD | Molding;Grinding;Cutting;Resin seal |